Shapemeter Roll

Shapemeter Roll

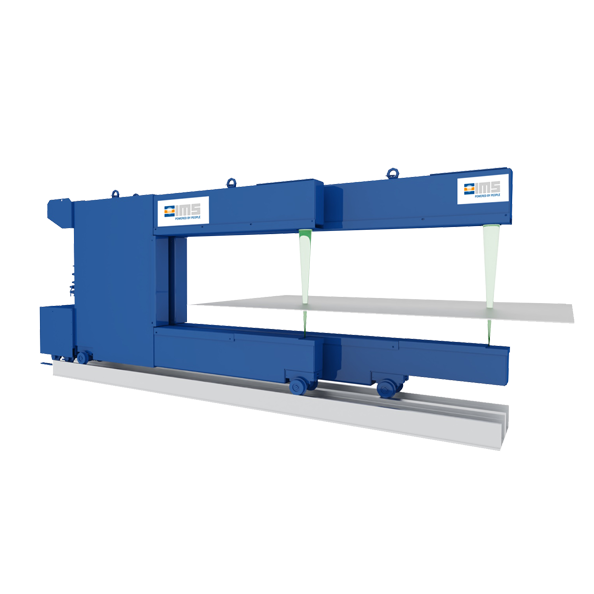

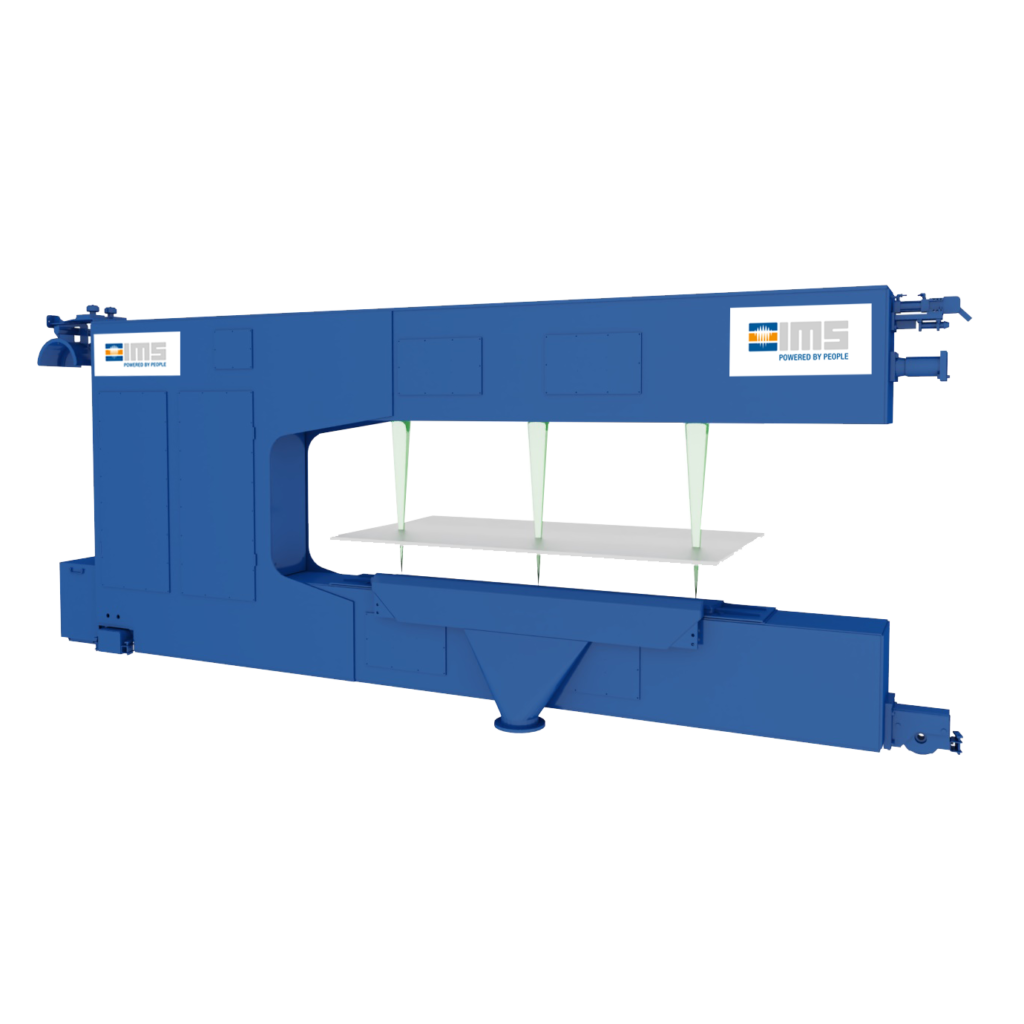

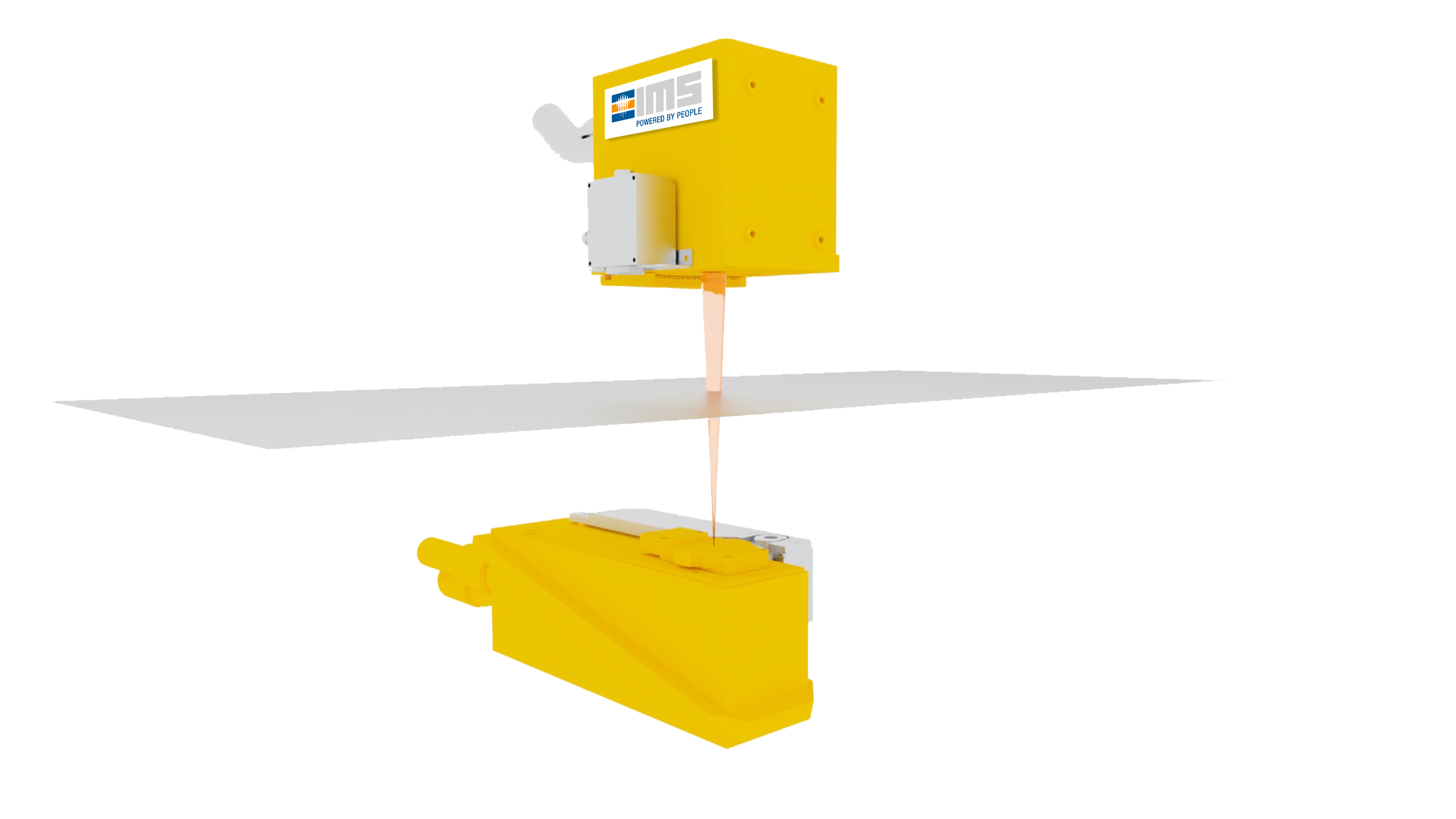

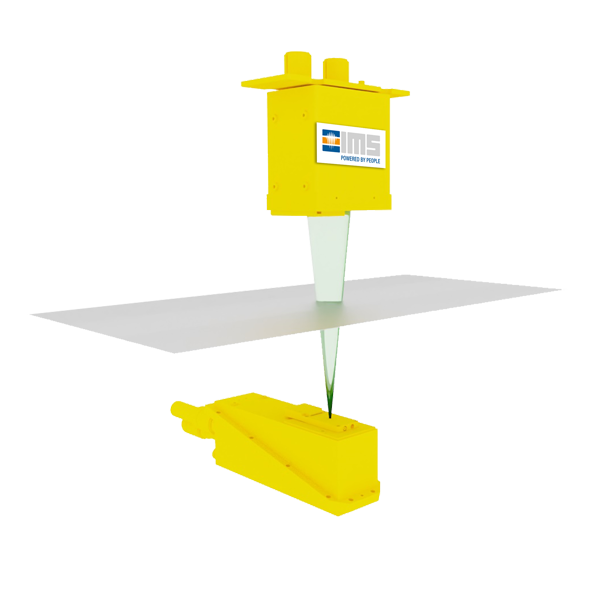

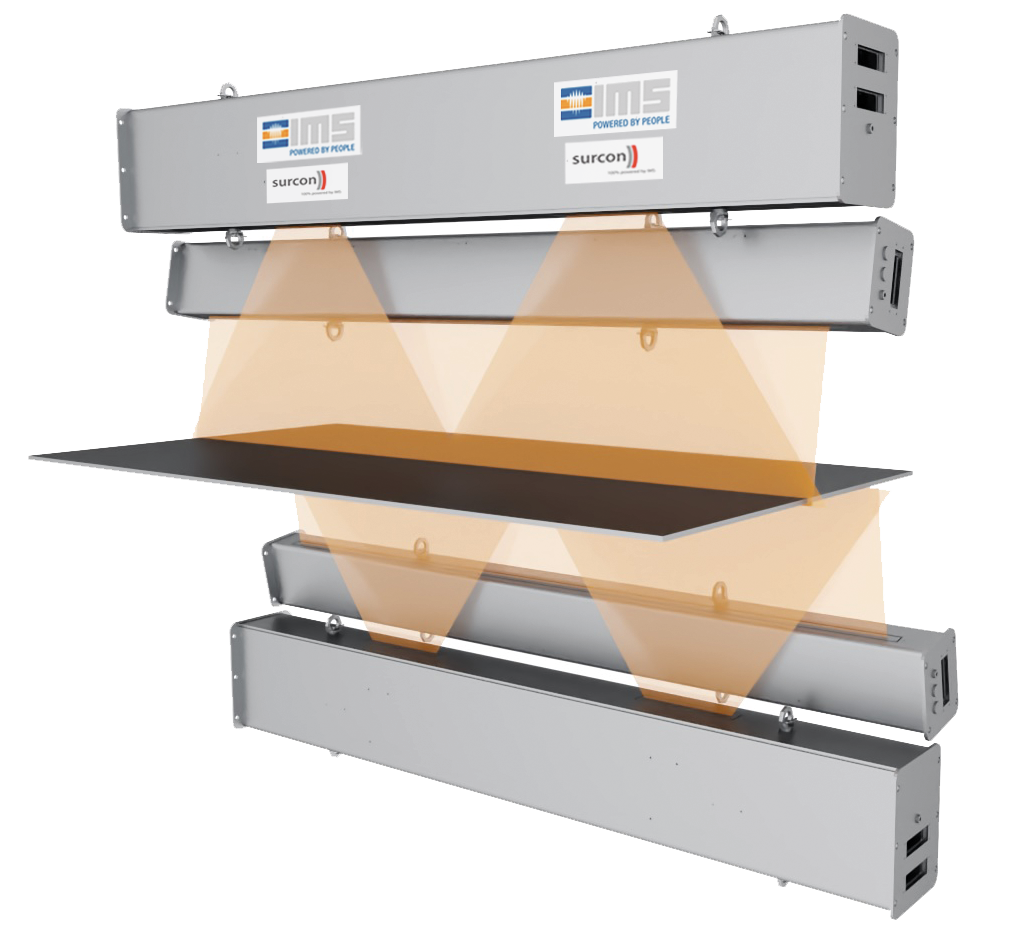

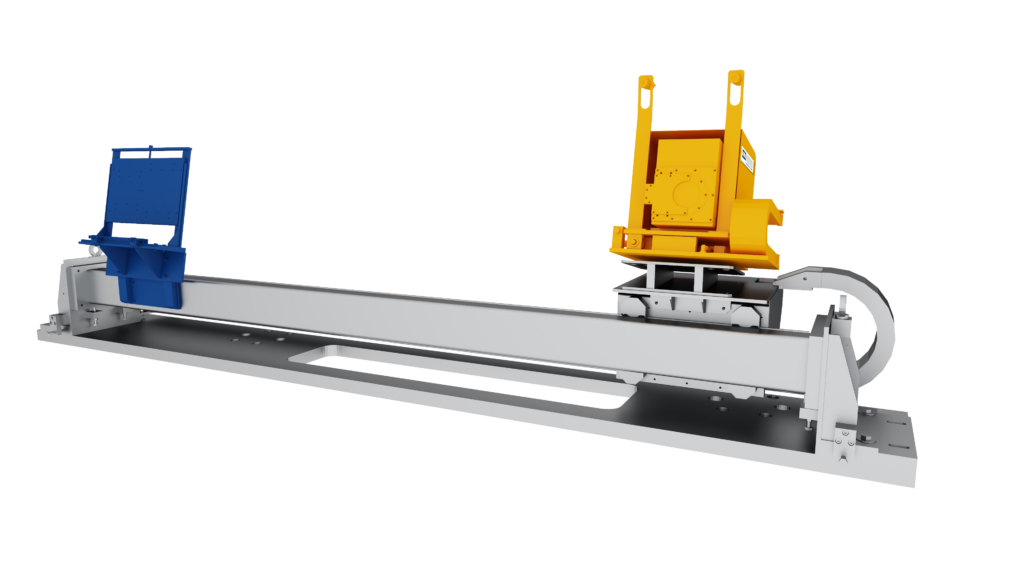

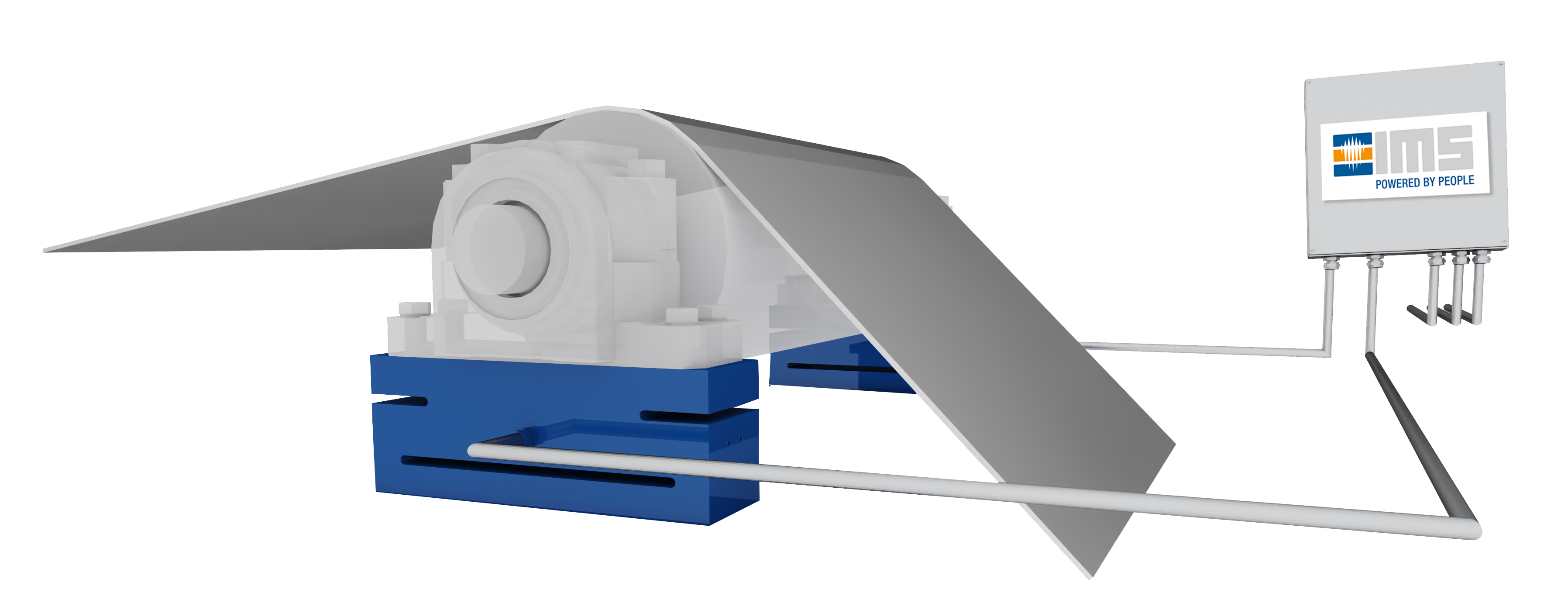

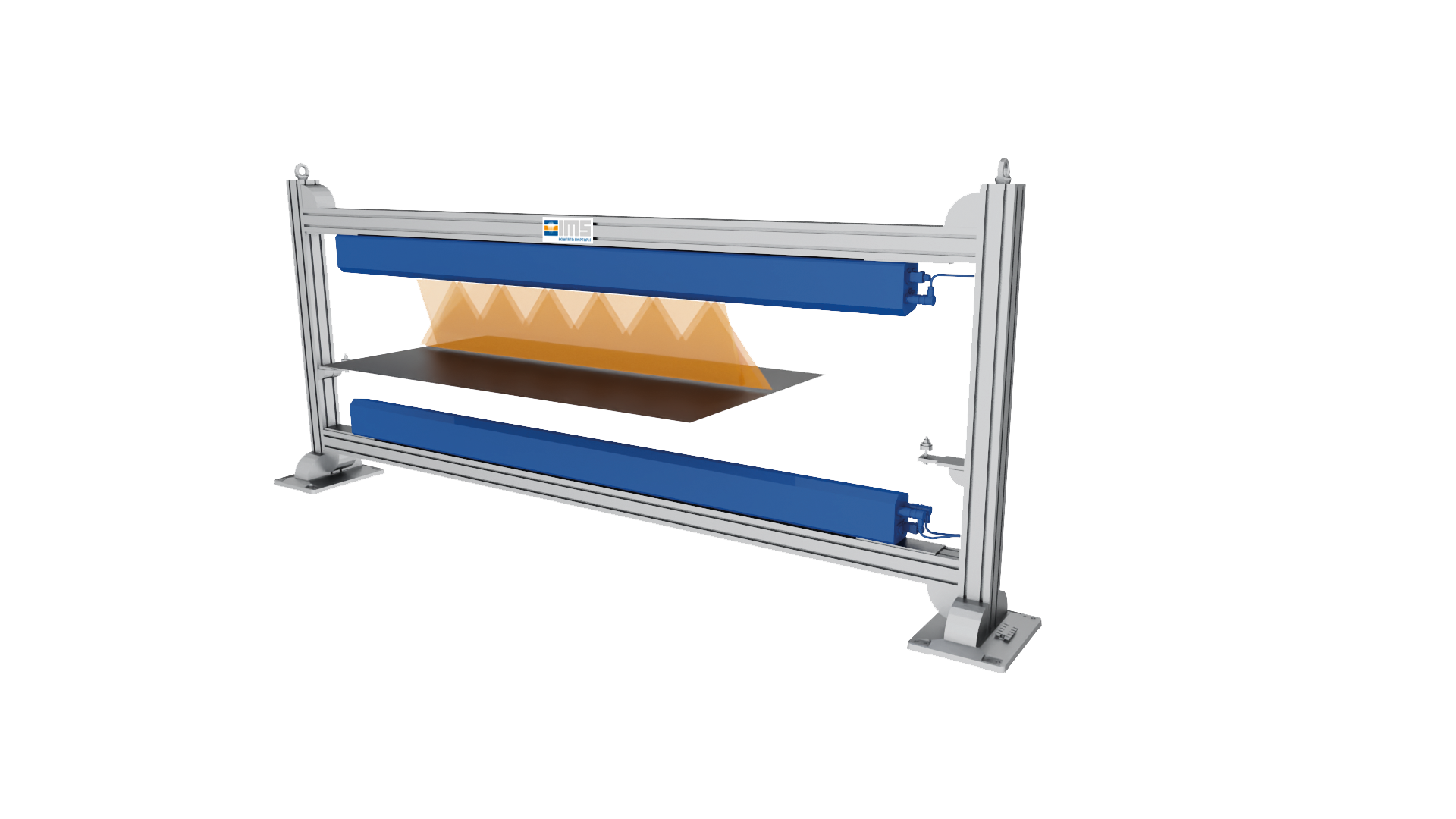

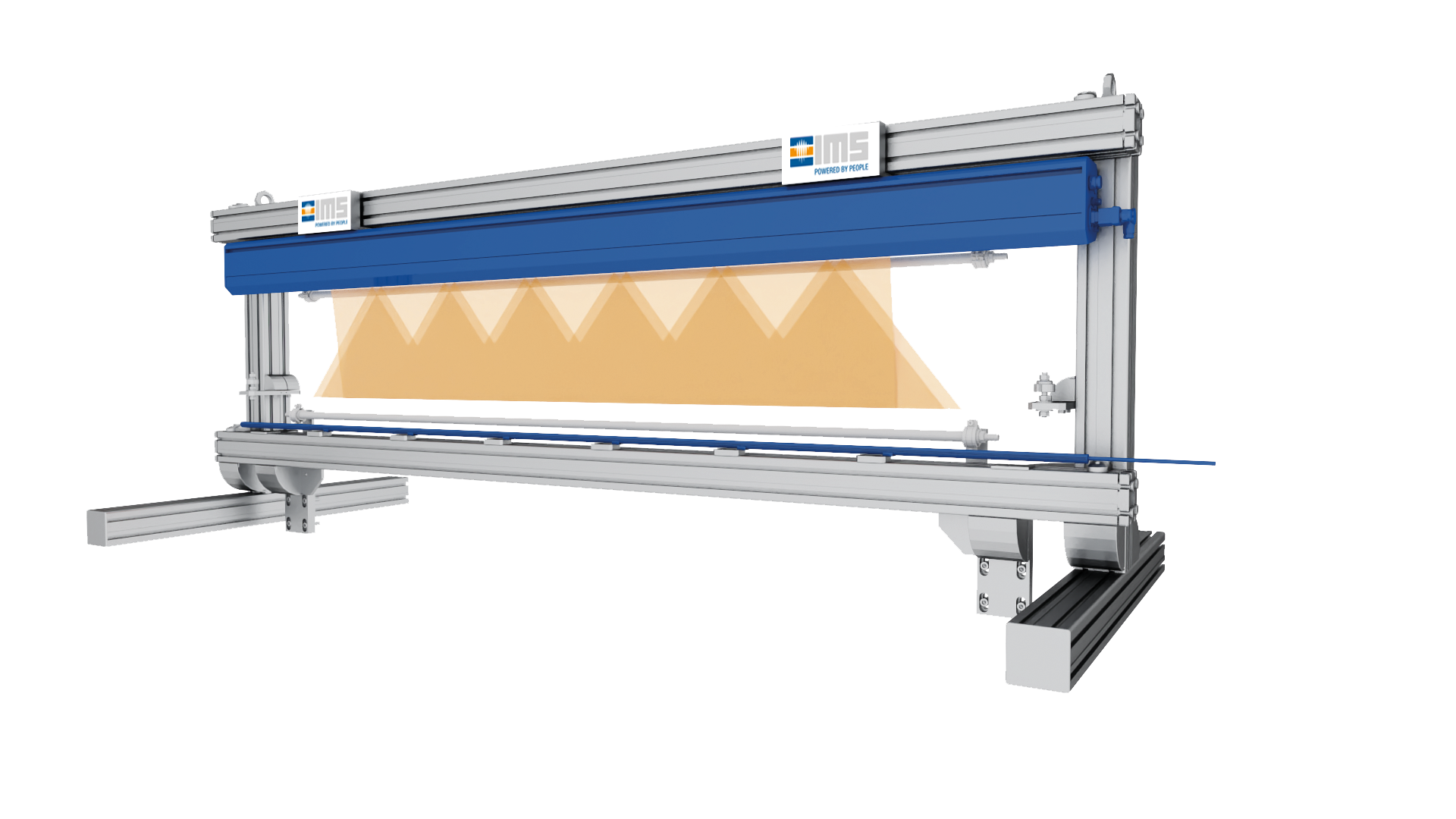

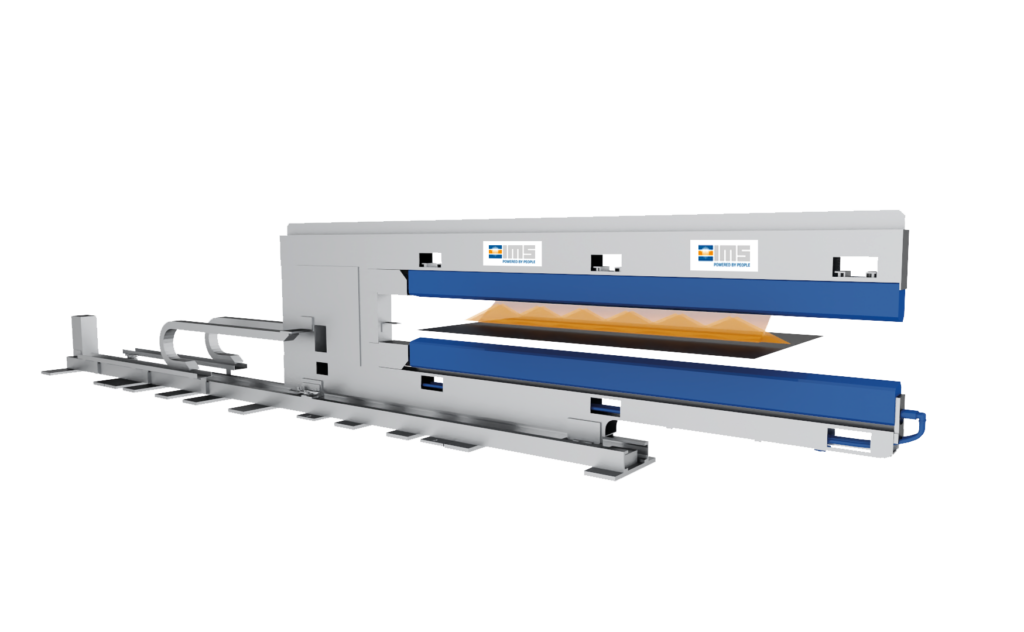

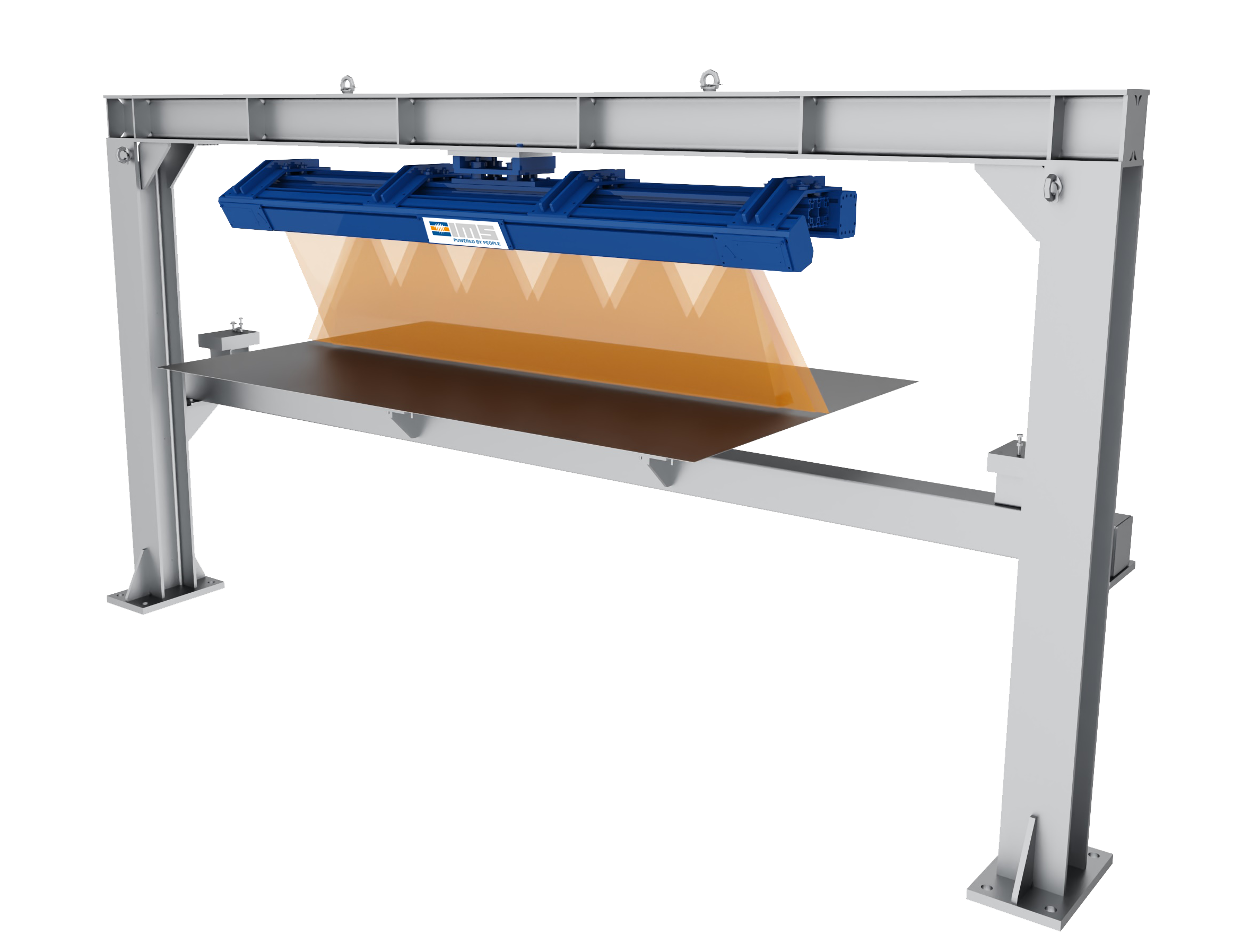

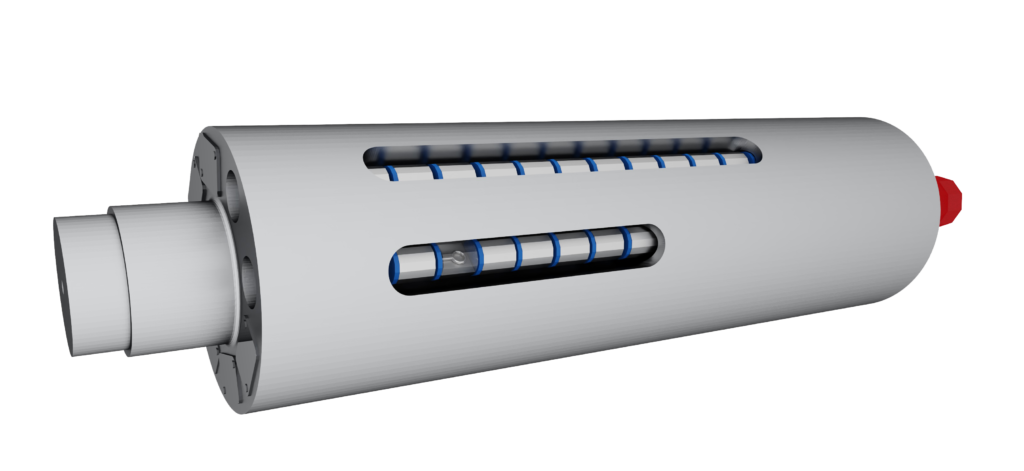

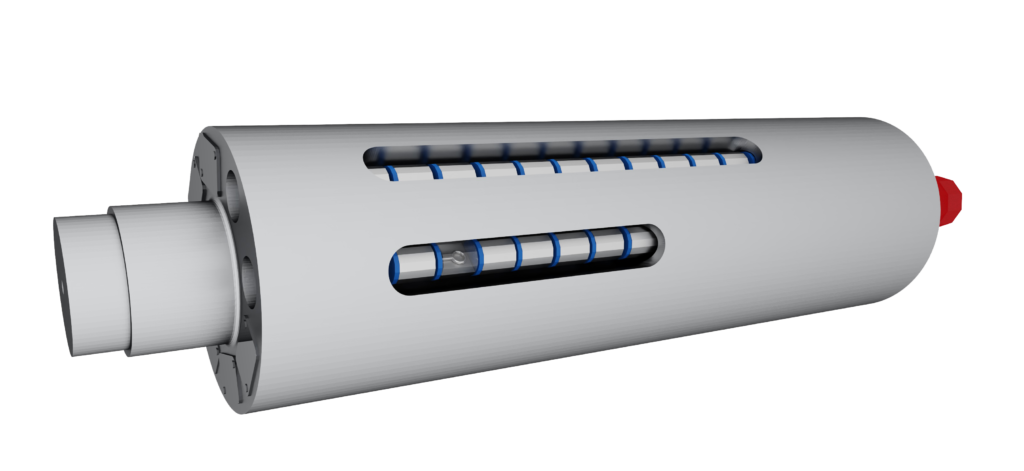

The shapemeter roll (BFI principle) consists of a solid roll body equipped with a project-specific number of piezoelectric sensors.

The sensors are distributed over the entire roller body as required for the specific measurement task.

The measured value of each sensor is amplified in the roll body, digitised and transferred from the rotating part (rotor) to the static part (stator) of the flatness measuring roll via an optical and wear-free rotary transmitter.

strip flatness measurement (tensile stress distribution)

optional:

– relative strip temperature profile measurement

– high temperature roll up to 300°C

– drive system

Special Features

- solid roller body (seamless)

- selectable roll diameter 200 – 500 mm

- selectable measuring zone widths 15 – 60 mm

-

roller surface:

- hardened & ground

- hard chrome

- tungsten carbide

- rubber coating

- low number of electronic and transmission units

- piezo-quartz sensors in single wire technology with low risk of failure

- maintenance-free and digital roller electronics with optical rotary transmitter

…to the verifiability of flatness previously required, your best customer suddenly also needs the exact geometry of the plates to be delivered. Do you now lose the order or is there a possibility to retrofit a measuring system despite the cramped conditions? What advantage does this investment bring me, apart from the fact that it satisfies just this one customer?

Not only in slitting and cut-to-length lines, but also in pickling lines, recoiling lines and inspection lines, it is necessary to meet growing customer demands on product quality. These are challenges that I am confronted with every day and for which we at IMS have developed a product portfolio specially tailored to metal service centres.

We set new standards with our systems and reach new dimensions with our efficient, digital and durable measurement technology. The systems are designed precisely for your application, and with our Life Cycle Partnership you are always on the safe side.”

Reserve your personal consultation appointment now!

Choose between a scheduled call back, a Teams video conference or simply use our contact form.

We look forward to hearing from you!

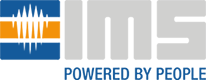

Shapemeter Roll

Shapemeter Roll

Technical Information

Material data

Typical thickness range:

0.006 – 10 mm, but not limited to

Max. speed:

2,000 m/min, but not limited to

Width:

up to 2,800 mm, but not limited to

Length:

not limited / continuous inspection

Measurement system data

Gauge type:

Force Measurement

(Piezo-quartz sensors in single wire technology)

Max. Measurement density (number of measurement points per metre of strip):

96 standard version

192 special version

Transmission:

contactless rotary transformer with charge amplifier

(24-channel standard version, 48-channel special version)

Measurement accuracy

Measuring range per zone:

0.2–60,000 N

Max. mechanical load per zone without the need to recalibrate the roll:

72,000 N

Dynamically measurable force change per zone:

0.2 N

Accuracy of the measuring device (2σ):

1I-Unit or 10 μm/m

Measure.Inspect.Detect.

Product Catalogue for Aluminium Rolling Mills

- Learn more about the product portfolio of our high-precision measuring systems for aluminium hot strip rolling mills and cold strip rolling mills

- Standard systems for measurement and detection of slab dimension, thickness, thickness profile, length, width, temperature, speed, 2D surface inspection as well as various special systems

- Special designs possible on customer request

IMS Measuring Systems for Aluminium Cold Rolling Mills

(Aluminium Hot Rolling Mills)

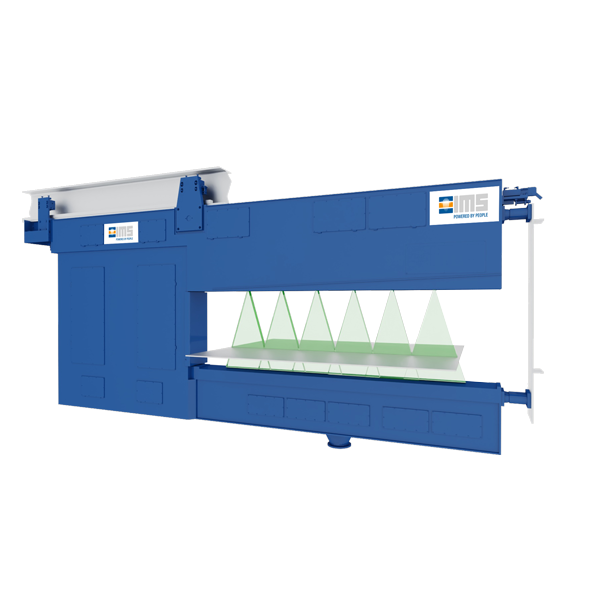

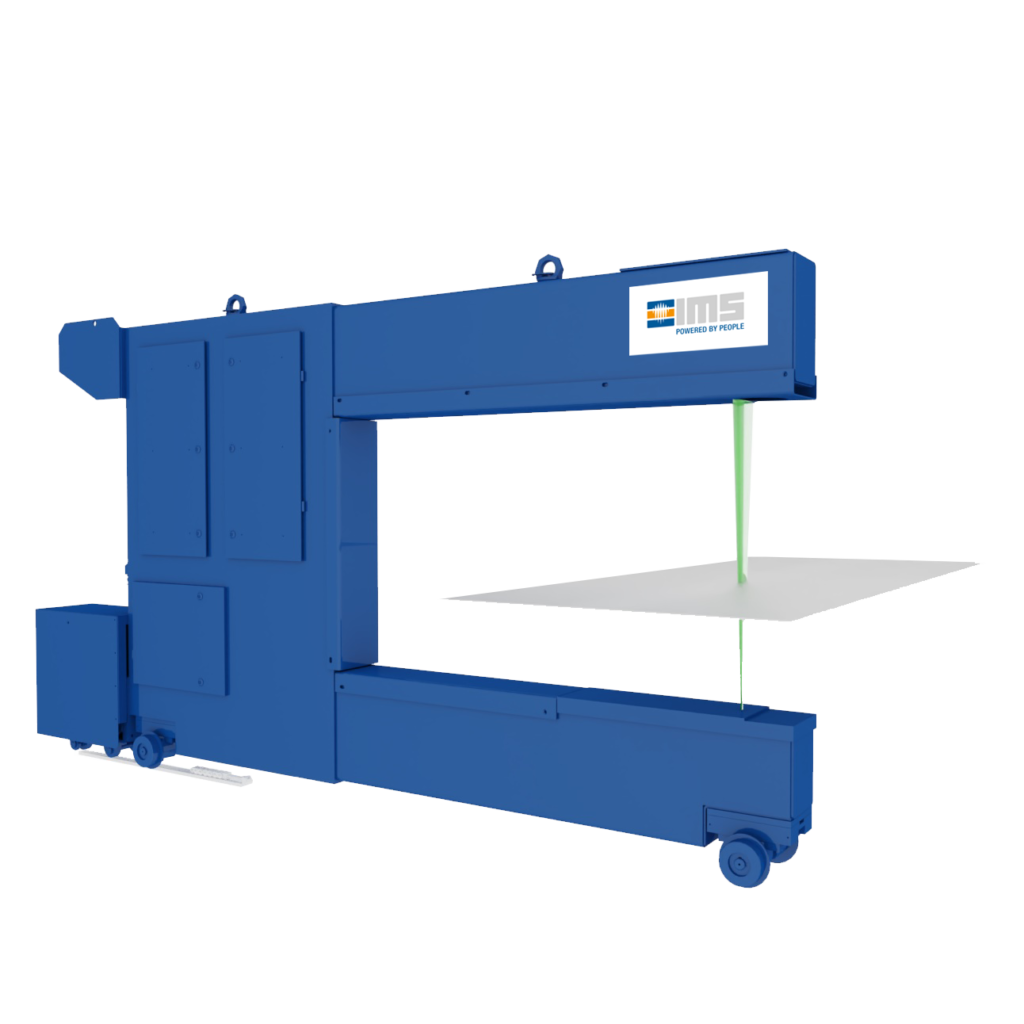

XR Traversing Thickness Profile Measuring System

(Aluminium Hot Rolling Mills)

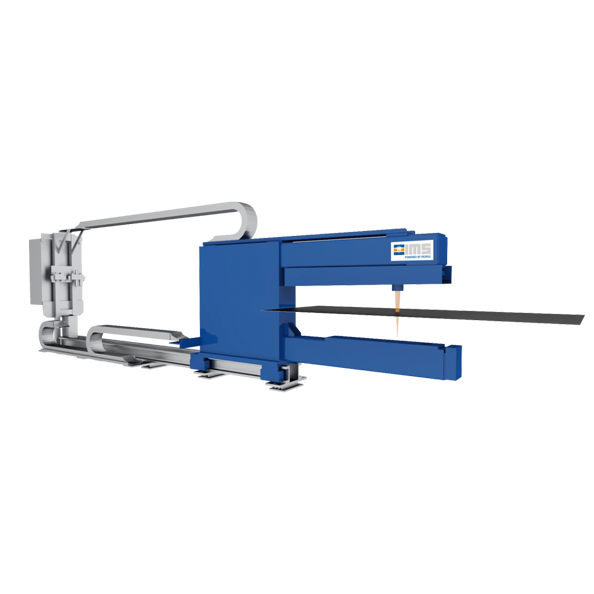

XR Traversing Thickness Profile Measuring System (cold rolling mill)

(Aluminium Cold Rolling Mills)

(Aluminium Cold Rolling Mills)

(Aluminium Cold Rolling Mills)

(Aluminium Cold Rolling Mills)