Laser

Centreline Thickness

Measuring System

Centreline Thickness

Measuring System

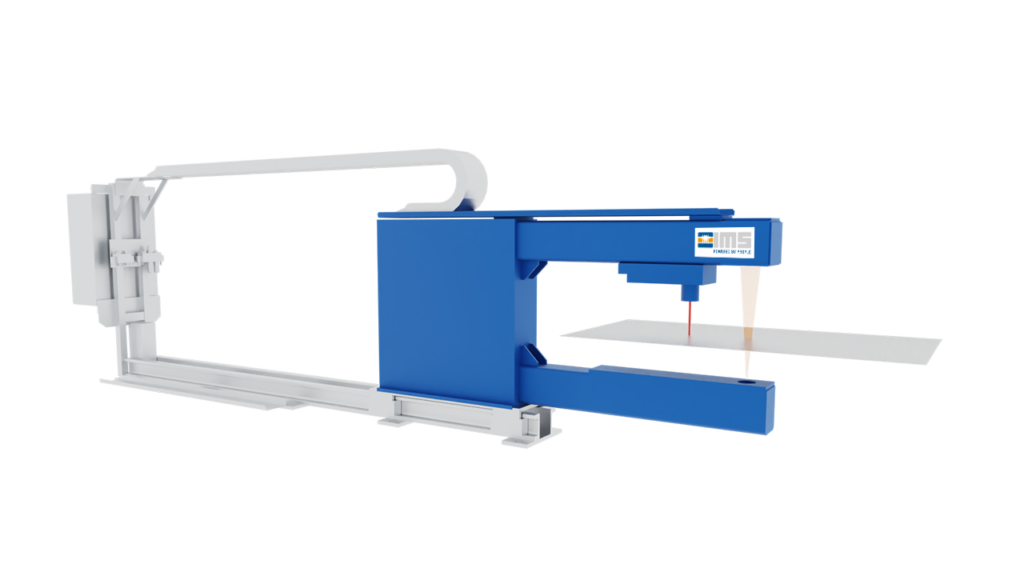

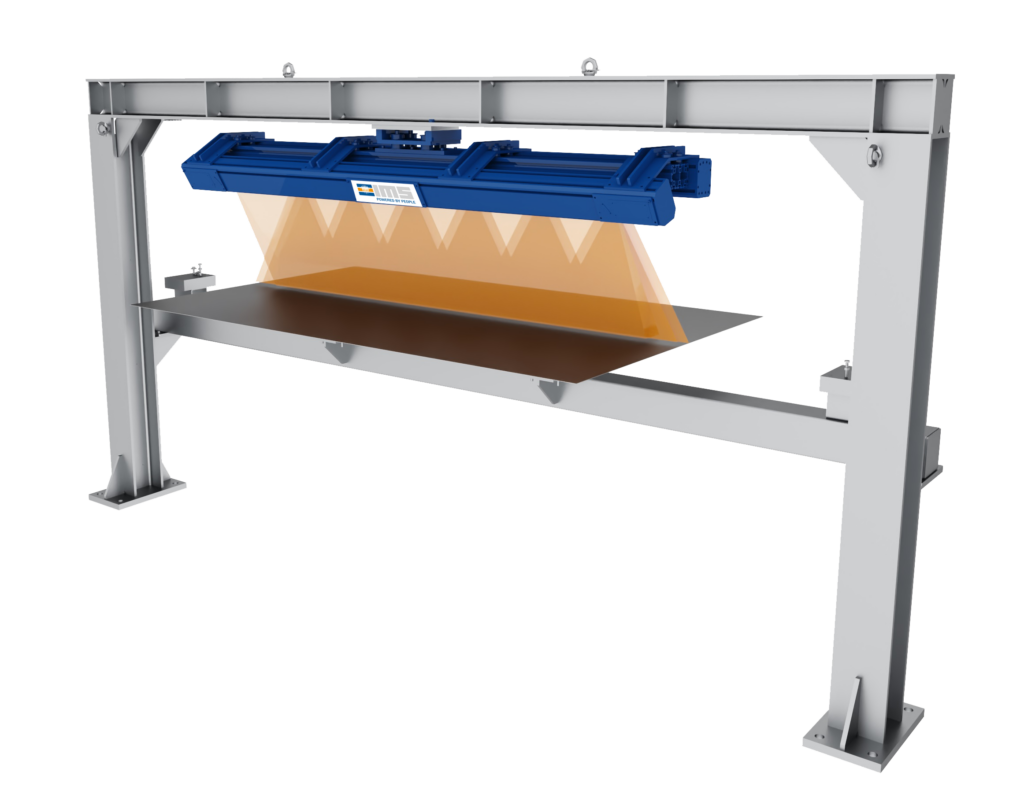

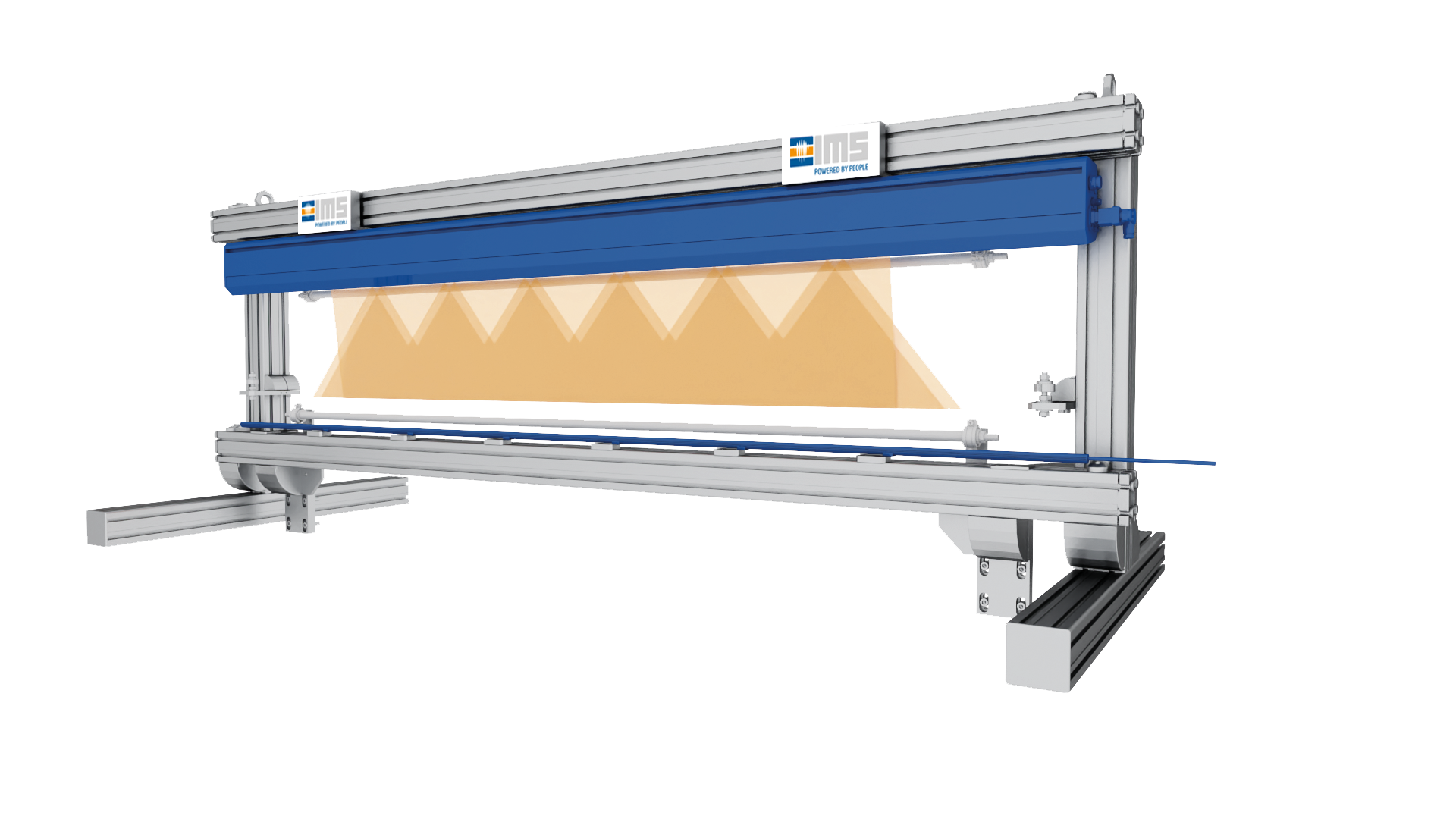

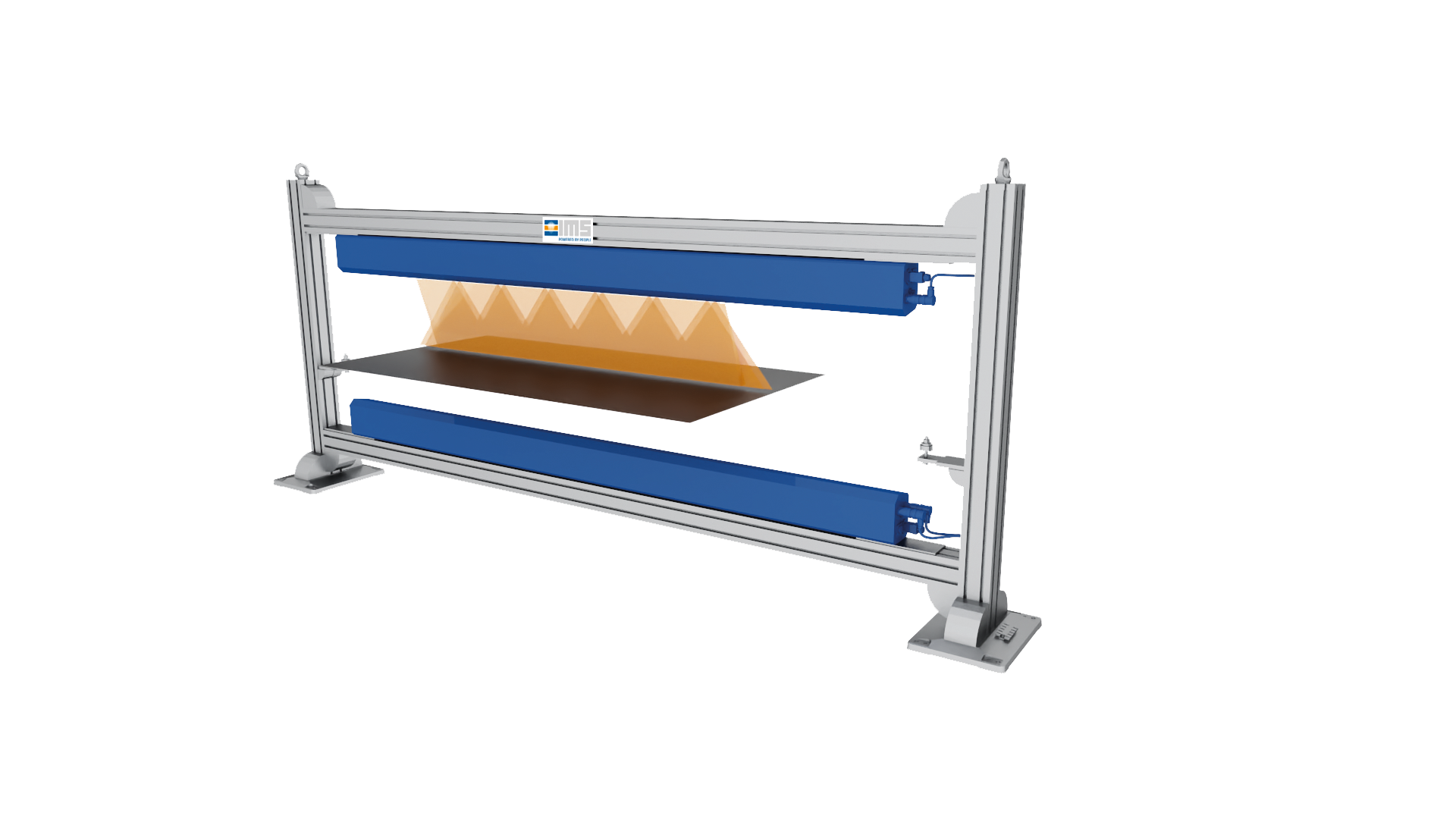

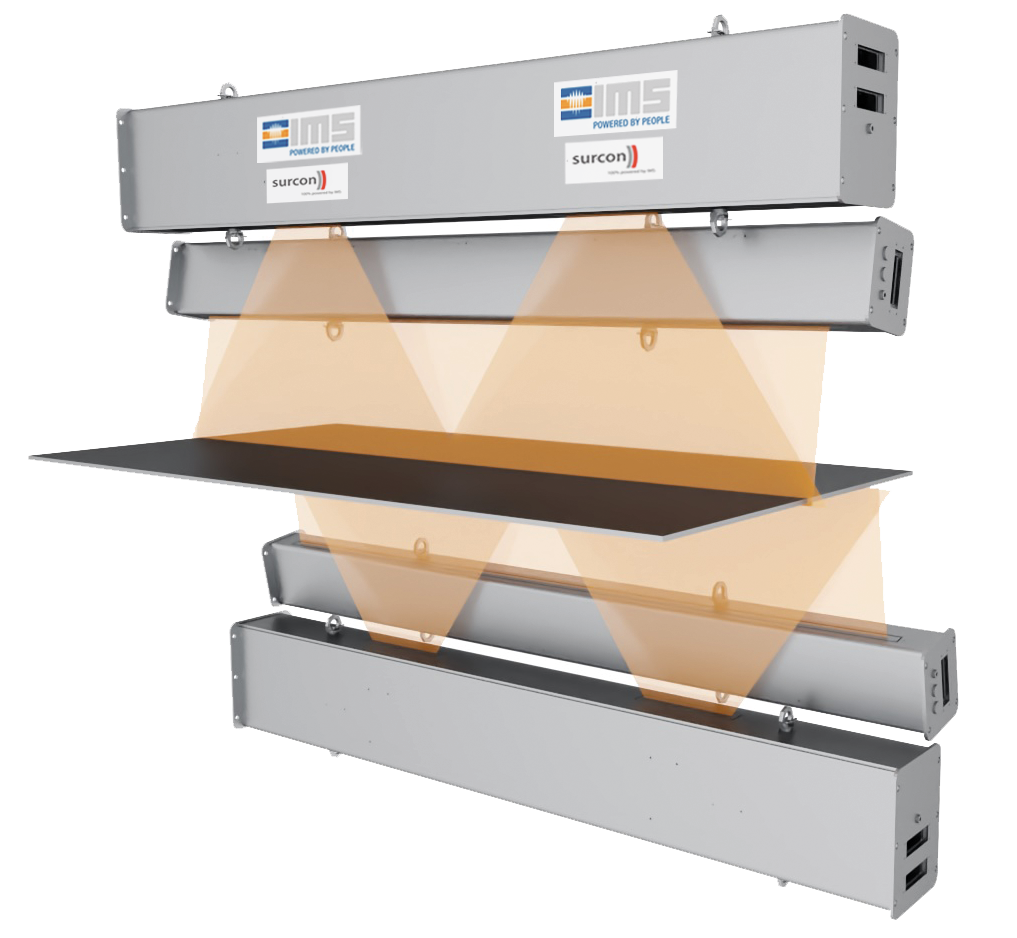

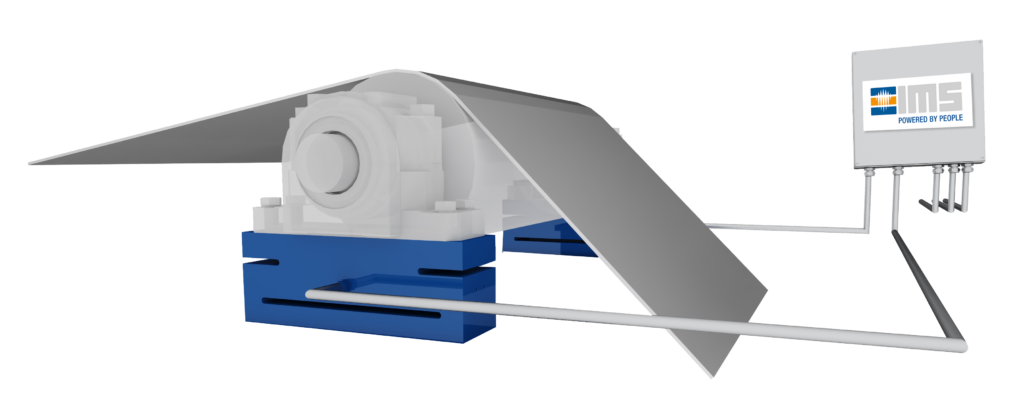

With its continuous, non-contact real-time measurement, the laser centreline thickness measuring system measures the thickness of the material in the centre of the strip.

Two laser triangulation sensors measure the distance from the top of the measuring system to the material as well as from the bottom. The actual thickness of the strip is determined accordingly from the difference between the geometric distance of the lasers to each other and the measured distance of the respective sensor to the material.

The measurement results are recorded and displayed by the visualisation software developed and produced by IMS.

centreline thickness

optional:

– strip thickness cross profile measurement

Special Features

- measurement on all surfaces

- customizable design and software

- alloy correction is not required

- open interfaces to customer

- remote maintainability

- application software is made among standard IEC 61131-3

- visualisation software is developed and made by IMS

do you have any questions?

#IMS Expert

Christian Knackstedt,

Dipl. Engineer

…for you as a specialist for cold rolling mills. One part of your solution here is offered by our innovative and high-precision measuring systems for the cold strip sector, which have proven that they measure and detect lastingly and reliably even under the most adverse environmental conditions.

How challenging and different such environmental conditions as well as the tasks assigned to you as the responsible person can be is something I am well aware of, not only theoretically but also practically, from more than 20 years of working for IMS. I started out as a systems engineer in the field of software and commissioning. Today, in the position of Global Sales Manager, I am your IMS expert for measuring systems in the cold strip sector.

Making measurable what can be measured is part of our corporate philosophy. The “how” in your particular case is as much my challenge from the moment you contact me as it is yours. My personal benchmark is your constant high product quality and – especially – your equally constant trust out of conviction in the performance of our measuring systems.”

Reserve your personal consultation appointment now!

Choose between a scheduled call back, a Teams video conference or simply use our contact form.

We look forward to hearing from you!

LASER

Centreline Thickness

Measuring System

Centreline Thickness

Measuring System

Technical Information

Material Data (Typical for Metal Service Centres)

Typical thickness range:

0.1 up to 8 mm, but not limited to

Speed:

400 m/min, but not limited to

Width:

up to 1,800 mm, but not limited to

Measurement System Data

Gauge type:

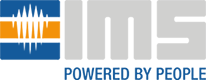

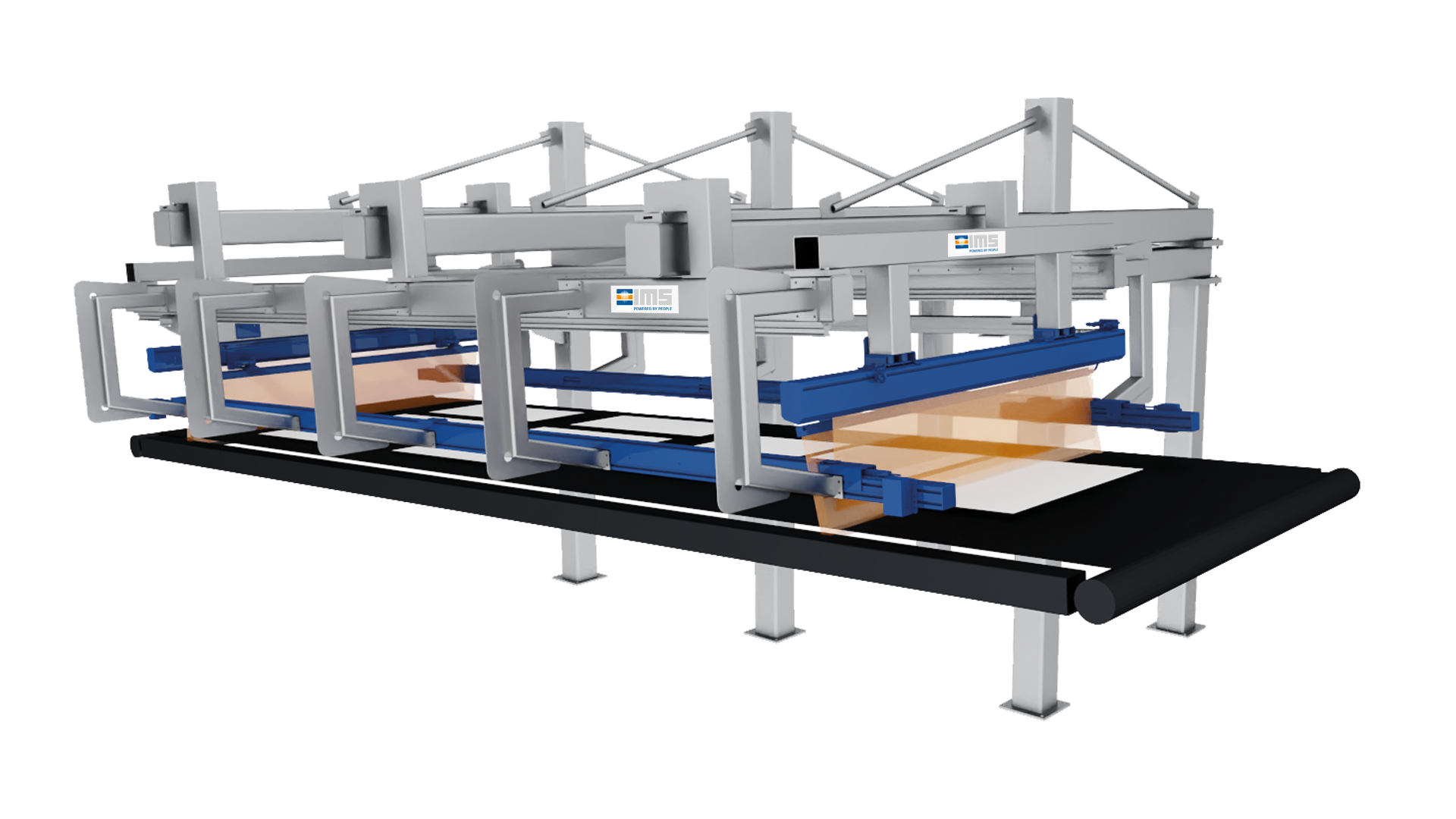

movable C-frame

Radiation source:

laser (class 2)

Measuring Dynamics

Cycle time data output:

2 ms

Measuring Accuracy (2 sigma values)

Reproducibility:

≤ ± 1.0 μm

Accuracy:

≤ ± 5 μm

Resolution:

0.1 μm

Measure.Inspect.Detect.

Product Catalogue for Metal Service Centres

- Learn more about the product portfolio of our high-precision measuring systems for metal service centres

- Standard systems for measurement and detection of thickness, width, slit strip width, sheet geometry, holes, pinholes, flatness, evenness, edgecracks, surface inspection, strip tension, web tension as well as various special systems

- Special designs possible on customer request

IMS Measuring Systems for Metal Service Centres

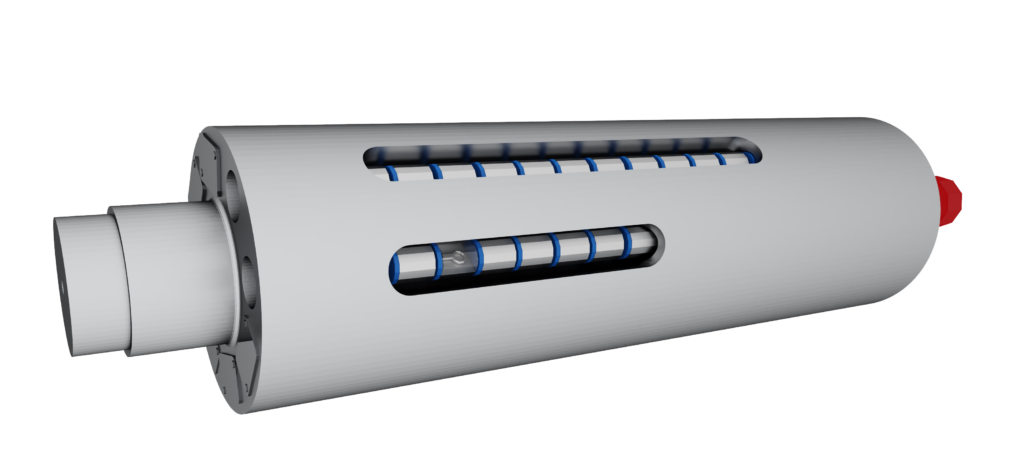

XR Traversing Thickness Profile Measuring System

(Metal Service Centres)