Surcon 2D

Surface Inspection System

Surface Inspection System

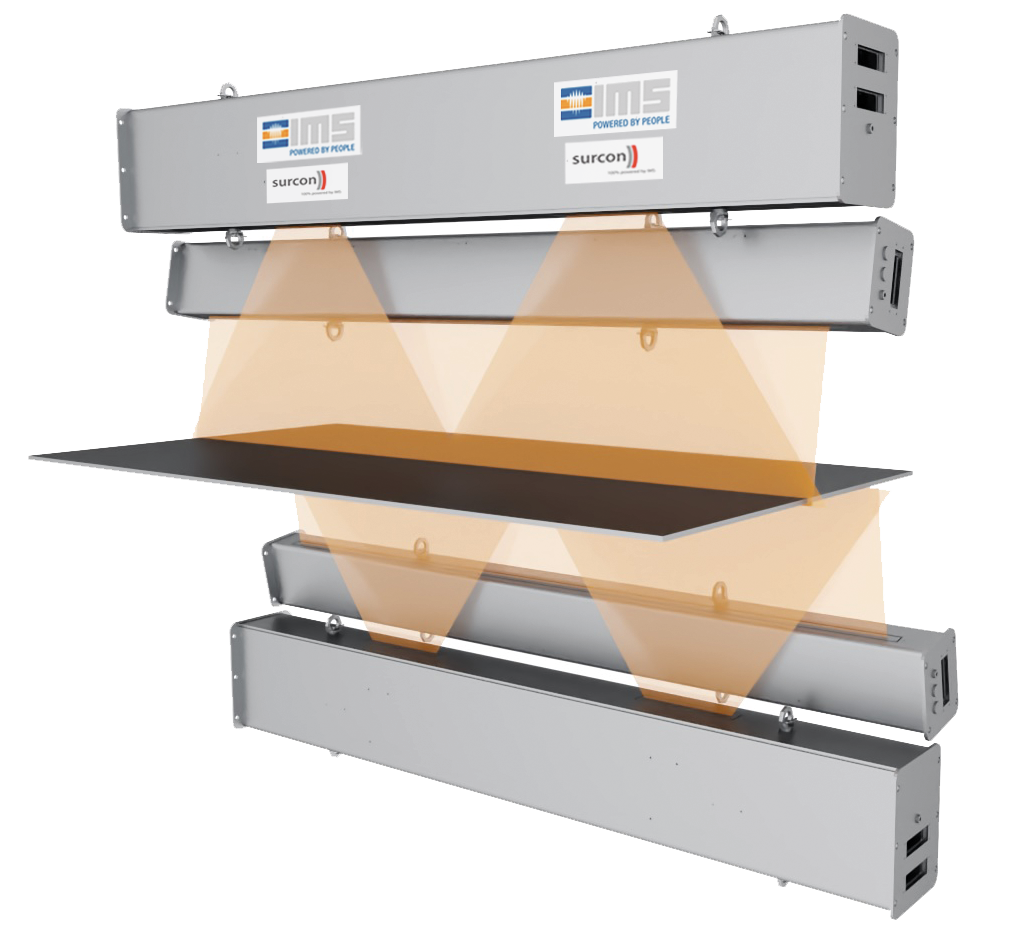

Surcon 2D surface inspection systems detect and visualise even the smallest defects and anomalies as online inspection systems. They impress with a synergy from decades of expertise in the development of precision measuring systems, combined with technically high-end surface inspection.

Surface inspection of the smallest defects is thus possible even under the most difficult conditions such as confined spaces, acidic vapours or oils. In addition, a powerful, intuitive HMI ensures that the most relevant measurement results are always available.

100% online inspection with fast line scan camera and high-performance LED

automated defect detection and classification

immediate detection of periodic defects indicating roll damage

Special Features

- reliable IMS hardware and housing with integrated cooling ensure long-lasting and low-maintenance operation

- customised solutions and individual adaptation to local conditions

- optional, integrated blower to protect the system from dust, dirt and splash water and to reduce maintenance requirements

- optionally available as C-frame for maximum convenience and easy maintenance in service position

- powerful toolsets for performance optimisation and data analysis

- apply surface inspection to each processing step for conclusive root cause analysis

- online visualisation of results and report generation via customised results interface

- integrated quality assessment tool – create your own rules for instant results evaluation

do you have any questions?

#IMS Expert

Thomas Köpsel,

Dipl. Computer Scientist

Reserve your personal consultation appointment now!

Choose between a scheduled call back, a Teams video conference or simply use our contact form.

We look forward to hearing from you!

Surcon 2D

Surface Inspection System

Surface Inspection System

Technical Information

Material data

Max. speed:

up to 1,900 m/min for 0.4 mm length resolution

Width:

not limited

Length:

no restriction / continuous inspection possible

Measurement system data

Configuration:

2D bright field

Installation type:

fixed installation or movable C-Frame

Camera type:

CMOS line scan camera / Gigabit Ethernet / Camera Link

Illumination source:

High Power LED 450 nm / 630 nm / white

more than 500 W/m² at 500 mm working distance

Typical working distance:

400-1,500 mm

Performance data

Chip size / framerate:

up to 8,192 pixels / up to 140 kHz

Typical resolution:

0.2 mm x 0.2 mm / 0.2 mm x 0.4 mm

Image storage:

defective areas in full resolution

full background in reduced resolution

short intervals can be stored in full resolution

Image storage capacity:

typical 60 TB

Image type:

open, lossless compressed tiff format

Database:

Microsoft SQL Server

Evaluation

Classification:

feature based, pre-trained AI

parallel classification using multiple classifiers

Features for classification:

up to >750 feature values per defect

Quality management:

rule based quality grading

Measure.Inspect.Detect.

Product Catalogue for

Aluminium Rolling Mills

- Learn more about the product portfolio of our high-precision measuring systems for aluminium hot strip rolling mills and cold strip rolling mills

- Standard systems for measurement and detection of slab dimension, thickness, thickness profile, length, width, temperature, speed, 2D surface inspection as well as various special systems

- Special designs possible on customer request