XR Triple-Head

Thickness Profile

Measuring System

Thickness Profile

Measuring System

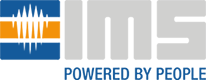

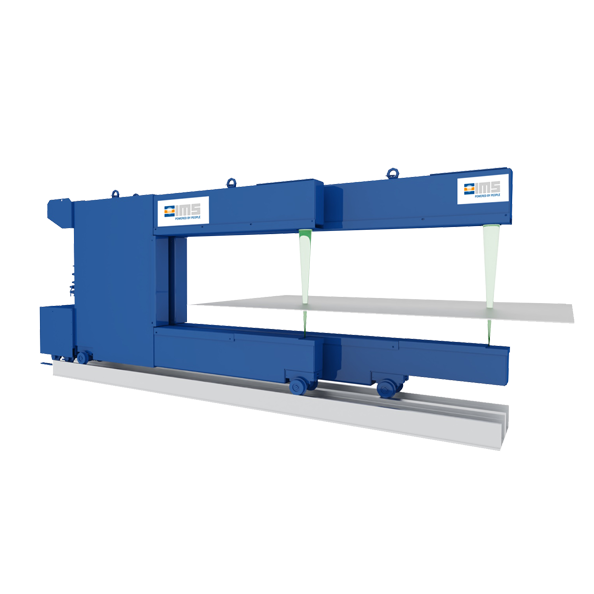

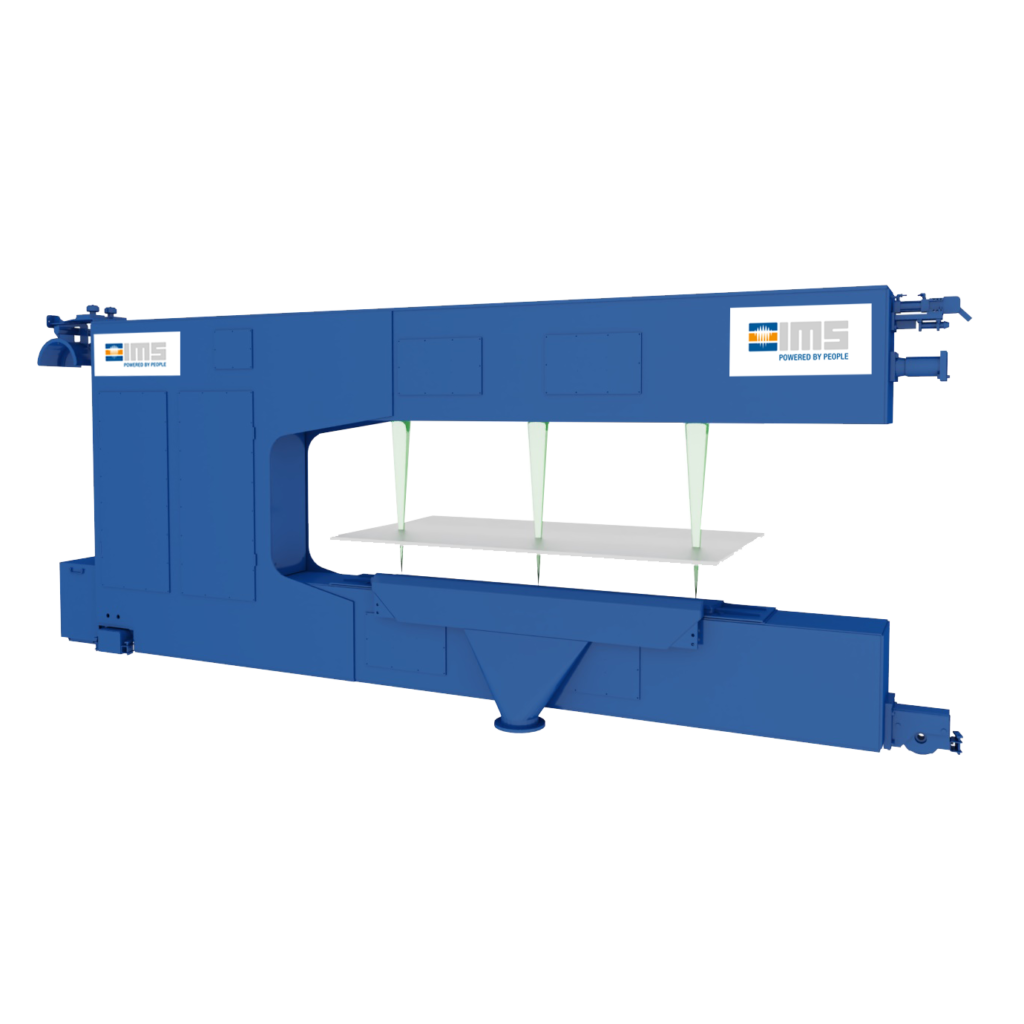

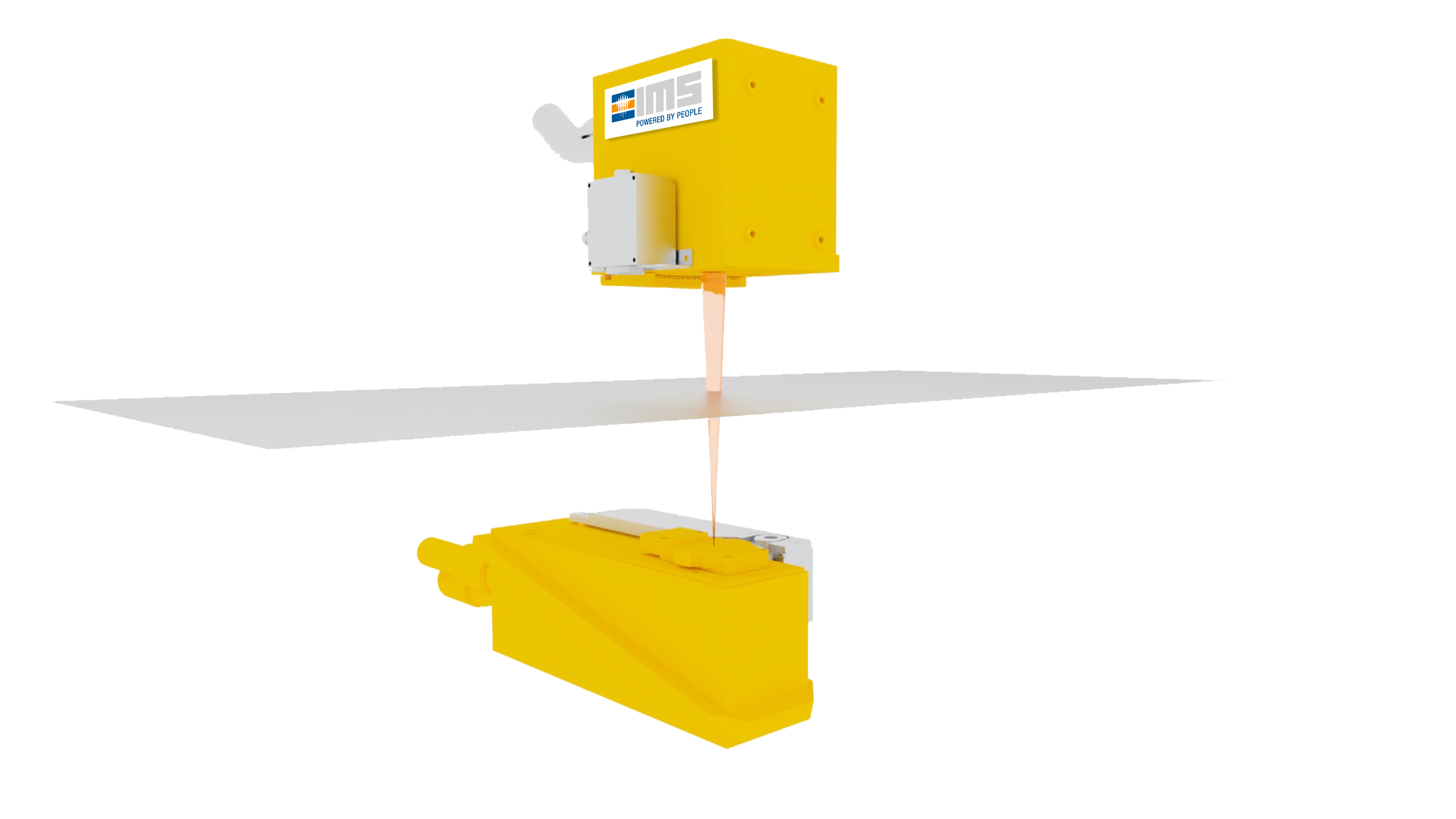

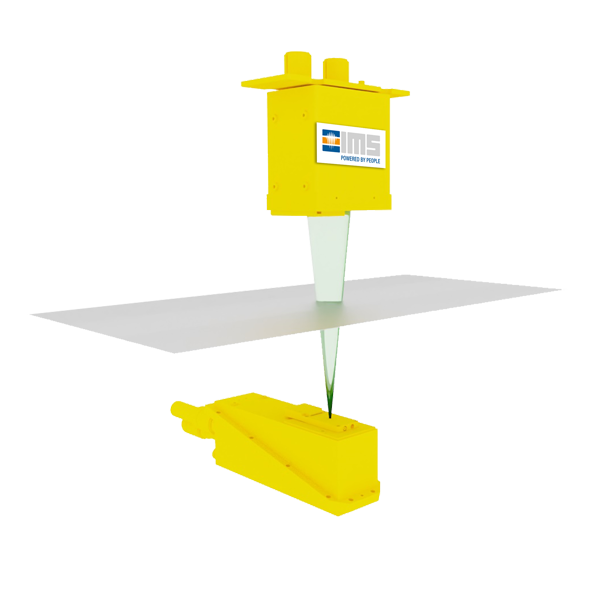

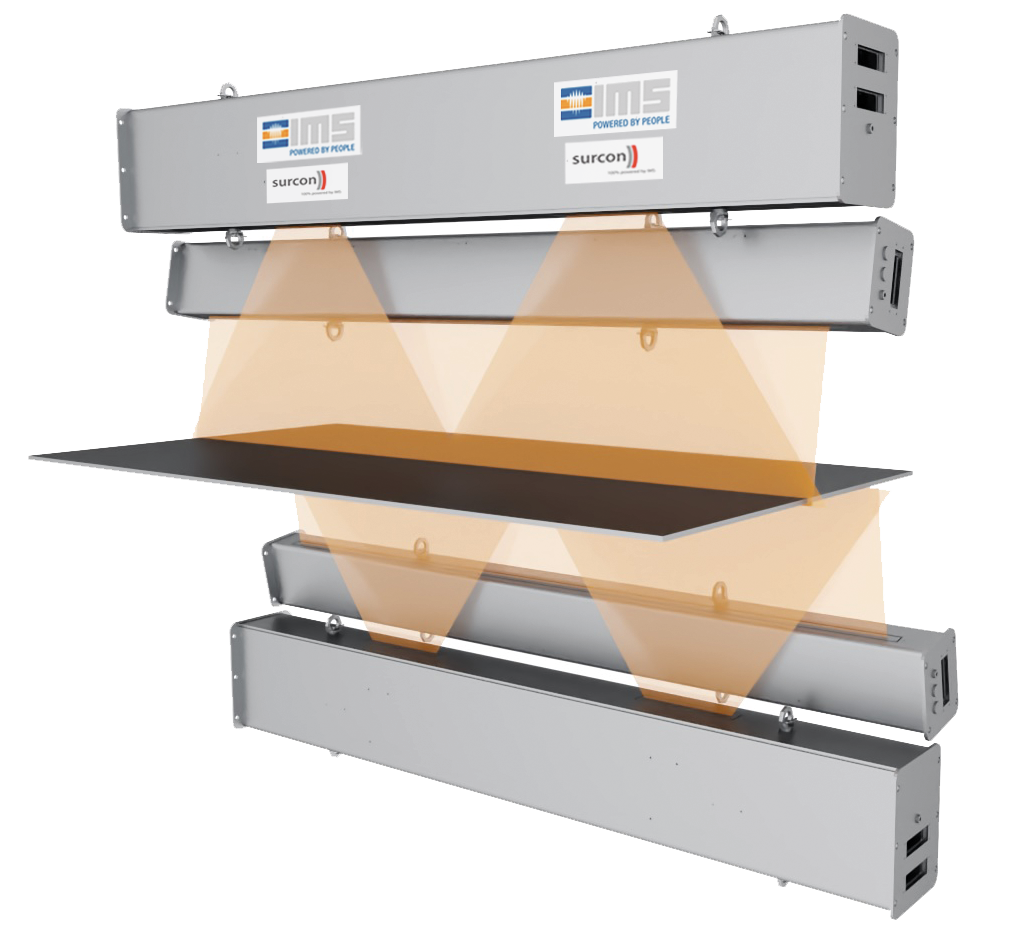

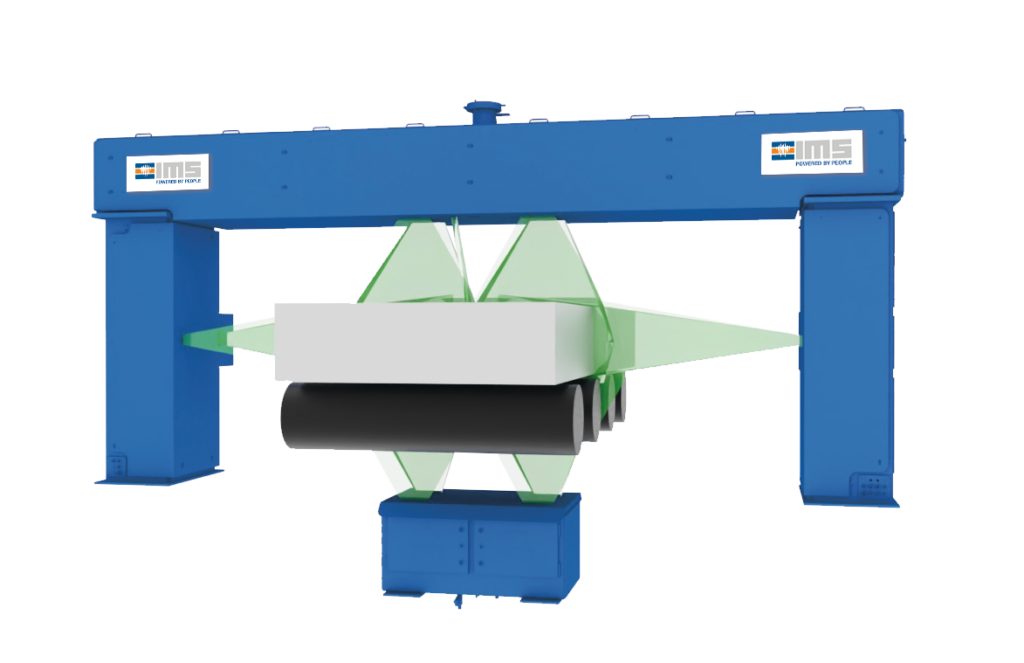

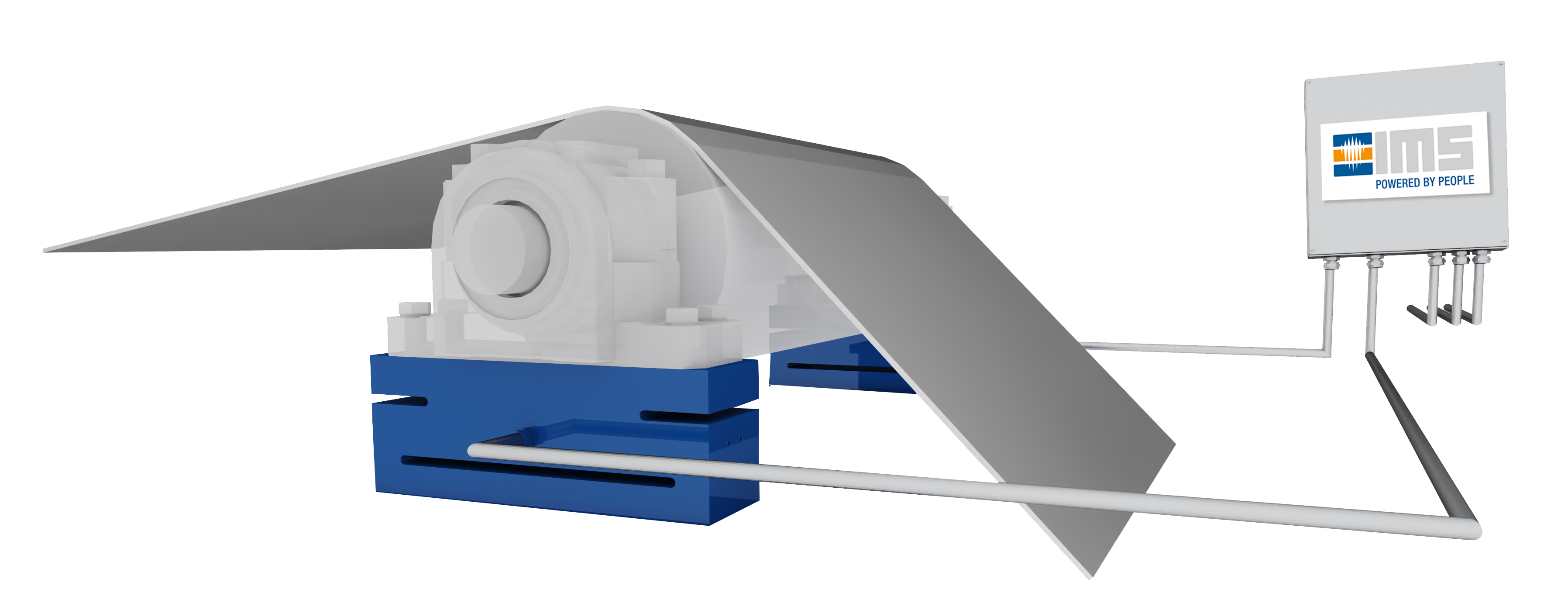

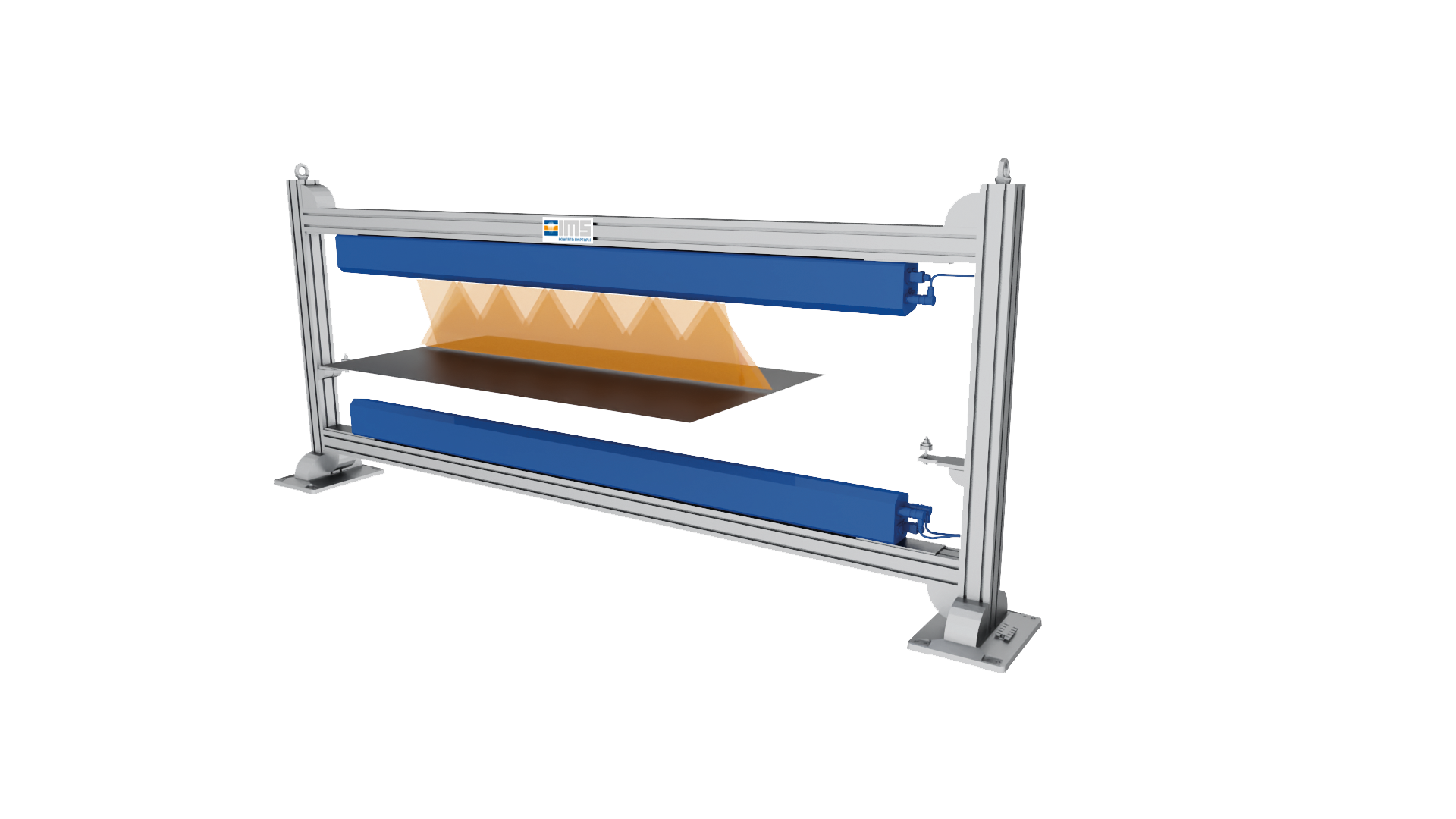

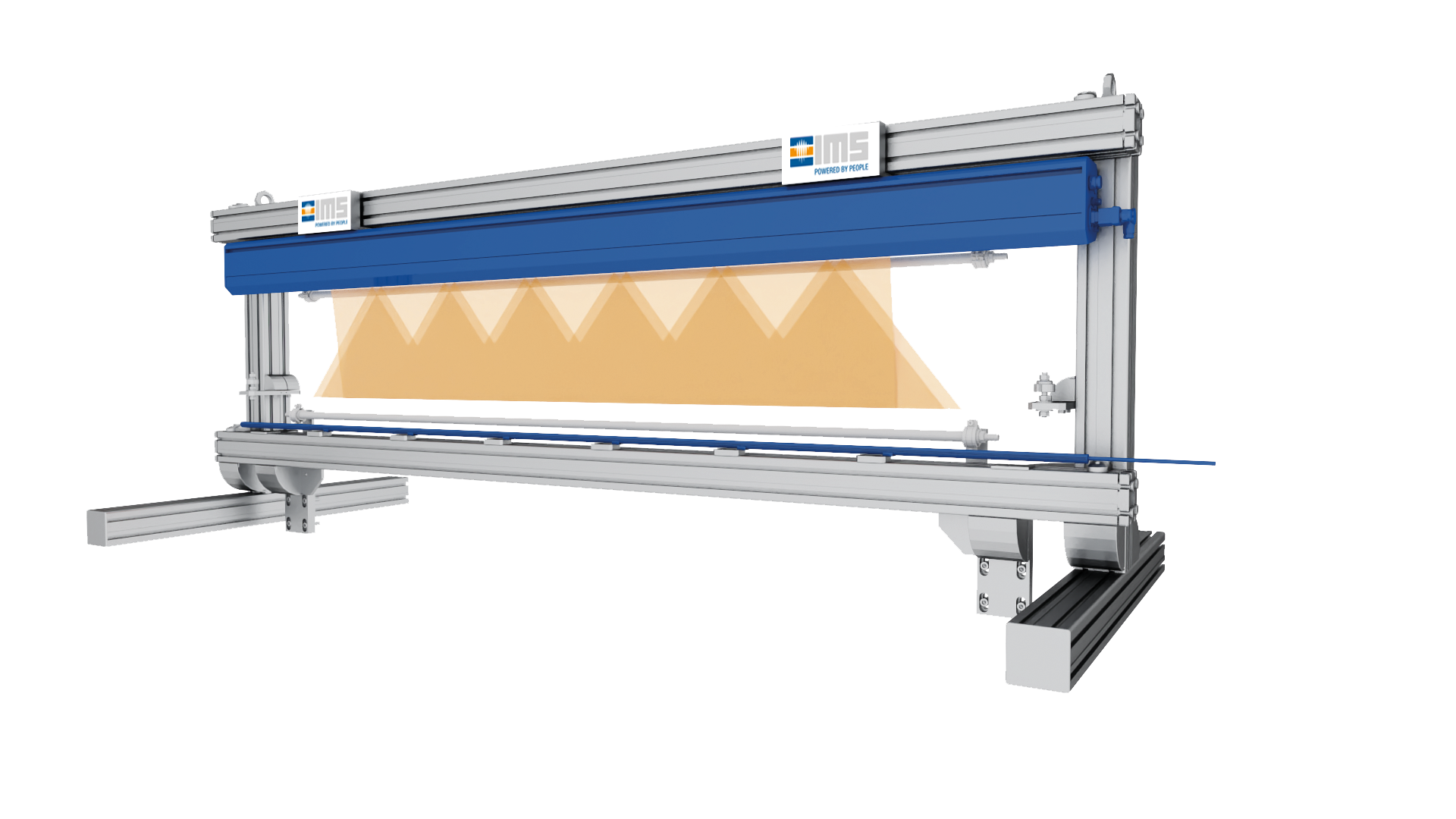

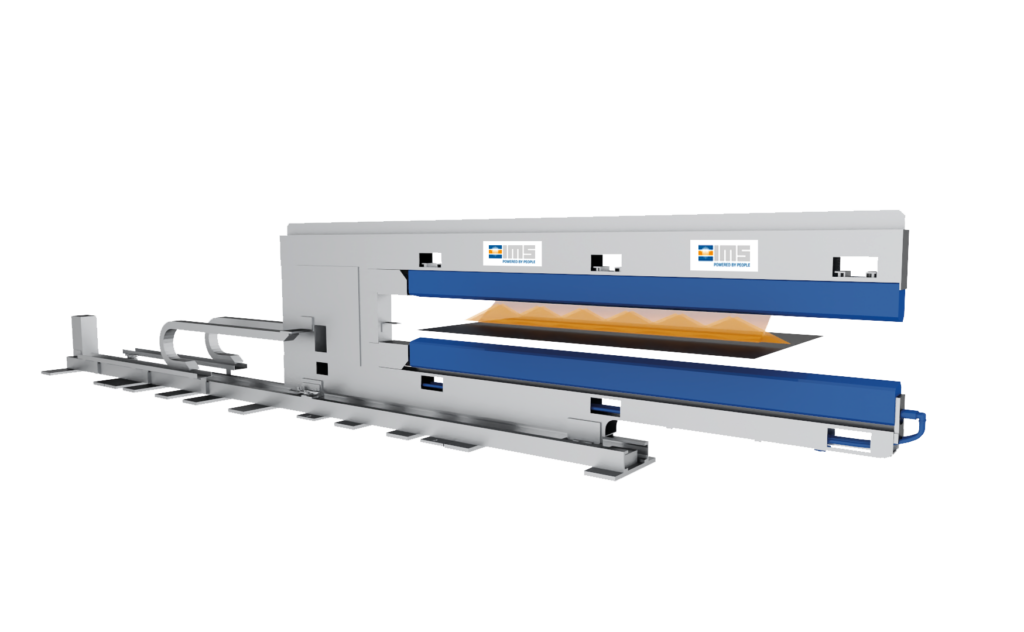

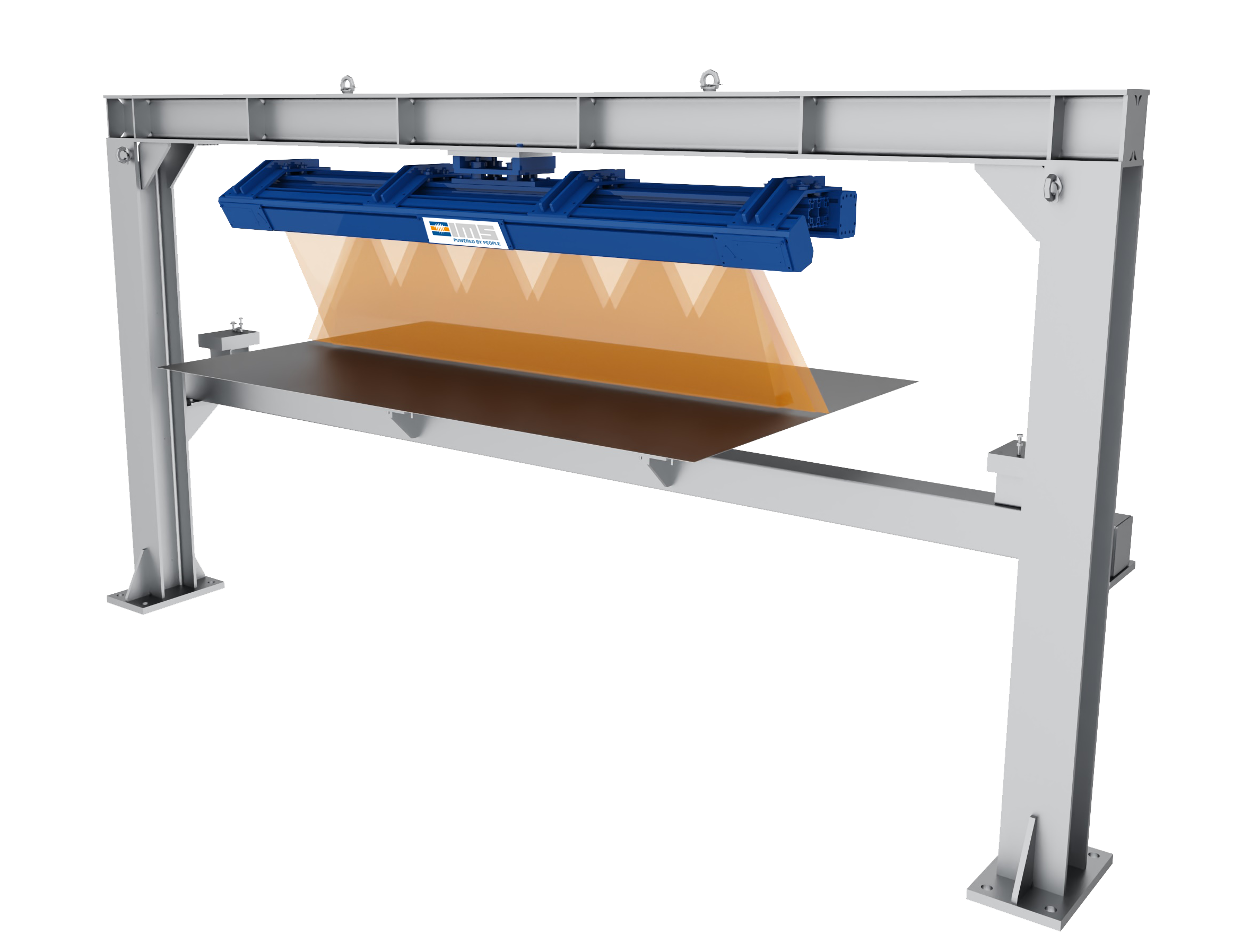

The XR triple-head thickness profile measuring system measures strip thickness and the thickness profile continuously and in real time.

The upper beam of the C-frame of the triple-head thickness profile measurement contains a task-based number of ionisation chambers to receive the radiation from the x-ray tubes installed in the lower beam. The ionisation chambers convert the thickness-dependent quantity of x-rays that pass through the material into electrical signals, which are then used to calculate the exact thickness of the material.

The centre measuring head of the system supplies the data for control (AGC) of the mill stand. The traversing outer measuring heads determine the thickness at the edges of the material for calculation of the important wedge and crown values.

continuous thickness measurement in the centre of the roller table

continuous measurement of the strip thickness profile by counter or synchronous traverse of the edge mea-suring heads

measurement of width and centreline deviation

calculation of wedge and crown values

faster cross-profile acquisition compared to an XR Twinset measuring system

permanent guarantee of centreline thickness measu-rement with the option to select the measuring head at will

Special Features

- c-frame with customisable dimensions

- optionally with integrated temperature measurement

-

x-ray high voltage generator:

- made by IMS Messsysteme GmbH, Germany

- compact system, easy installation

- no or reduced maintenance intervals for the connectors of the high voltage cable

- constant x-ray high voltage, no standard magazine required

-

ionisation chambers (detectors):

- made by IMS Messsysteme GmbH, Germany

- pluggable design

- no separate cooling necessary

- mechanically highly resilient

- very long service life

- excellent stability (drift behaviour)

- redundancy when using multiple detectors

do you have any questions?

#IMS Expert

Martin Schulte im Walde

…These are particularly impressive due to their long service life and constant performance.

Our measuring systems allow our customers to always be one step ahead of the competition.

Our motto of “Precision out of passion and quality out of conviction” is the decisive criterion for the development of our high-precision measuring systems, many of which have been and still are world firsts.

To be allowed to actively support this pioneering spirit for more than 30 years, as well as our passion for precision, is a challenge anew for me every day, which continues to motivate and inspire me even after all these years.

For me, it’s not enough to just talk about the matter. You have to speak to the people and therefore it is my personal goal to guide you through the buying process with the quality of my advice and my support, to develop with you exactly the measuring system that is right for your specific measurement tasks and that has been specially tailored to your individual application.”

Reserve your personal consultation appointment now!

Choose between a scheduled call back, a Teams video conference or simply use our contact form.

We look forward to hearing from you!

XR Triple-Head

Thickness Profile

Measuring System

Thickness Profile

Measuring System

Technical Information

Material data

Typical thickness range:

> 0 mm up to max. 180 mm

Speed:

> 0 – 12 m/s

Width:

up to 4,300 mm

Measurement system data

Gauge type:

movable c-frame

Radiation source:

X-ray tube (approx. 180 kV/ 2.5 mA, depending on the measuring task)

Measuring dynamics

Analogue time constant:

approx. 10 ms

Cycle time data processing:

10 ms

Cycle time data output CL:

10 ms

Cycle time data output profile:

after full cross profile scan (depending on strip width)

Measuring accuracy

Reproducibility:

≤ 0.07%

Linearity:

≤ 0.05 %

Long term drift (10 hrs):

≤ 0.1 %

Statistical noise (10 ms):

≤ 0.1 %, not better than ±10 μm (for the max. thickness range)

Measure.Inspect.Detect.

Product Catalogue for Aluminium Rolling Mills

- Learn more about the product portfolio of our high-precision measuring systems for aluminium hot strip rolling mills and cold strip rolling mills

- Standard systems for measurement and detection of slab dimension, thickness, thickness profile, length, width, temperature, speed, 2D surface inspection as well as various special systems

- Special designs possible on customer request

IMS Measuring Systems for Aluminium Hot Rolling Mills

(Aluminium Hot Rolling Mills)

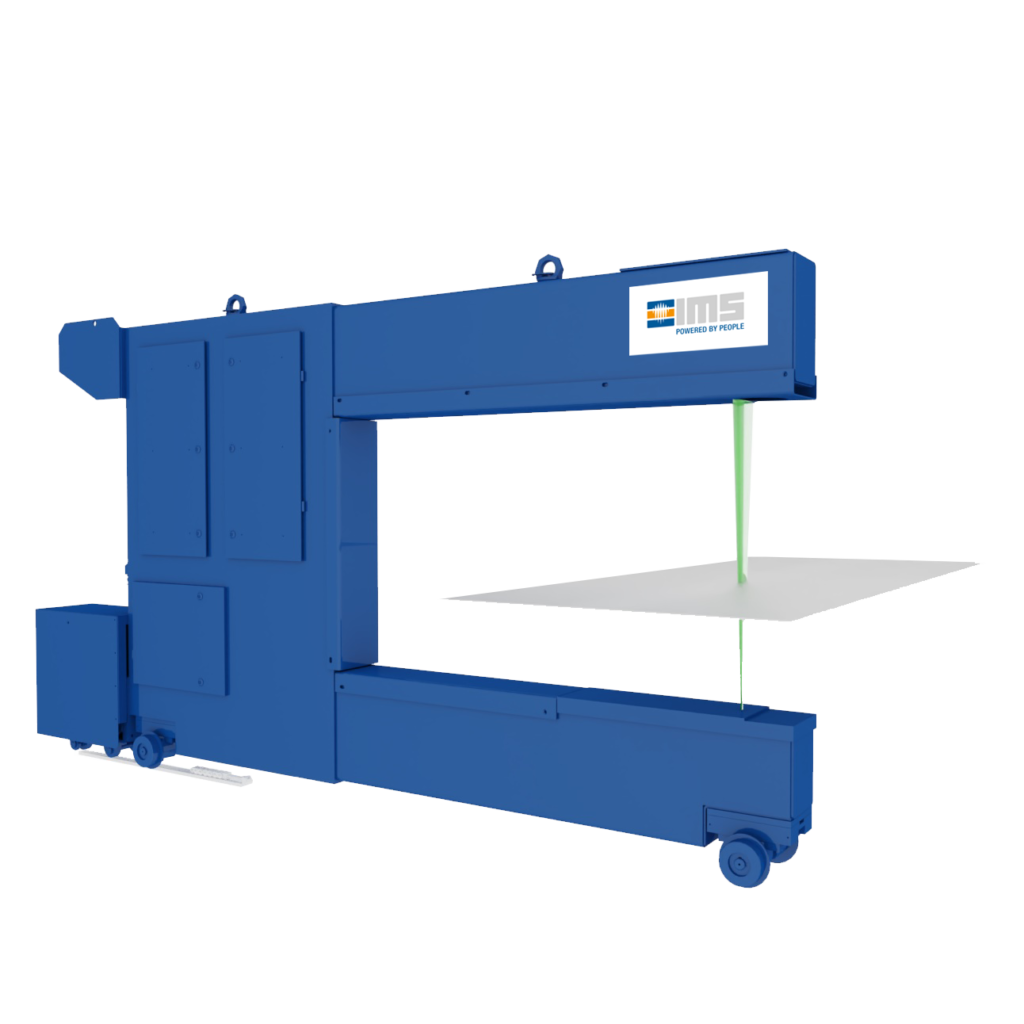

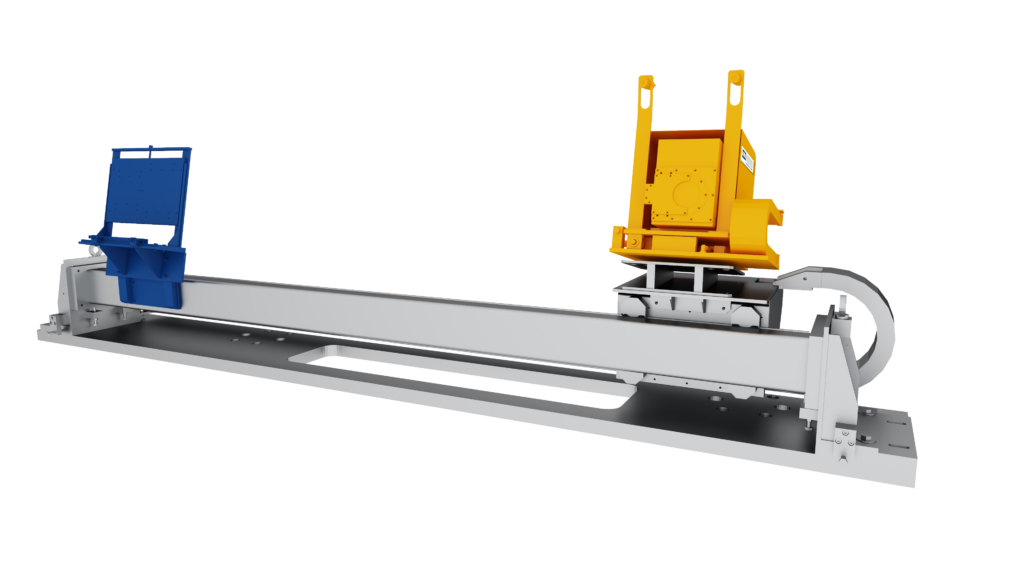

XR Traversing Thickness Profile Measuring System

(Aluminium Hot Rolling Mills)

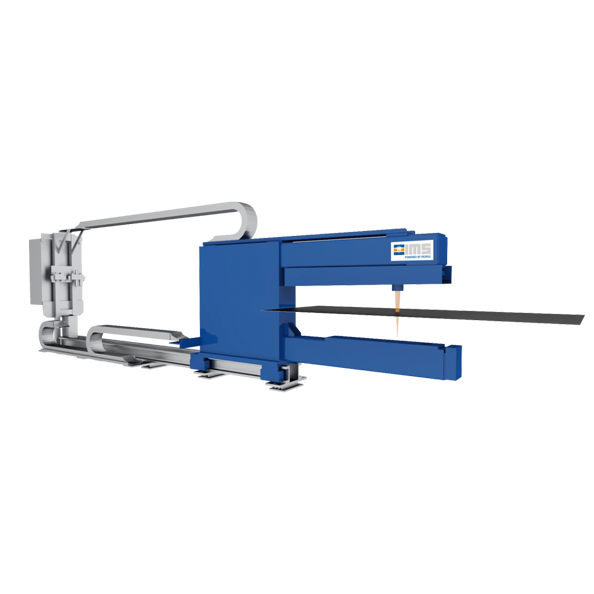

XR Traversing Thickness Profile Measuring System (cold rolling mill)

(Aluminium Cold Rolling Mills)

(Aluminium Cold Rolling Mills)

(Aluminium Cold Rolling Mills)

(Aluminium Cold Rolling Mills)