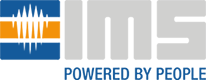

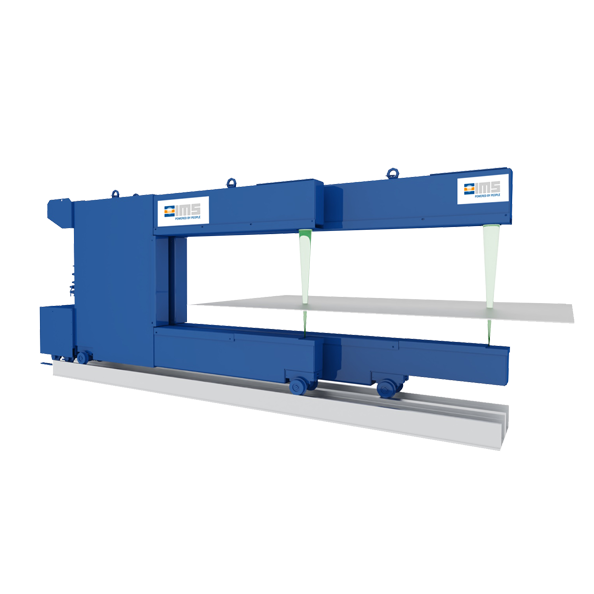

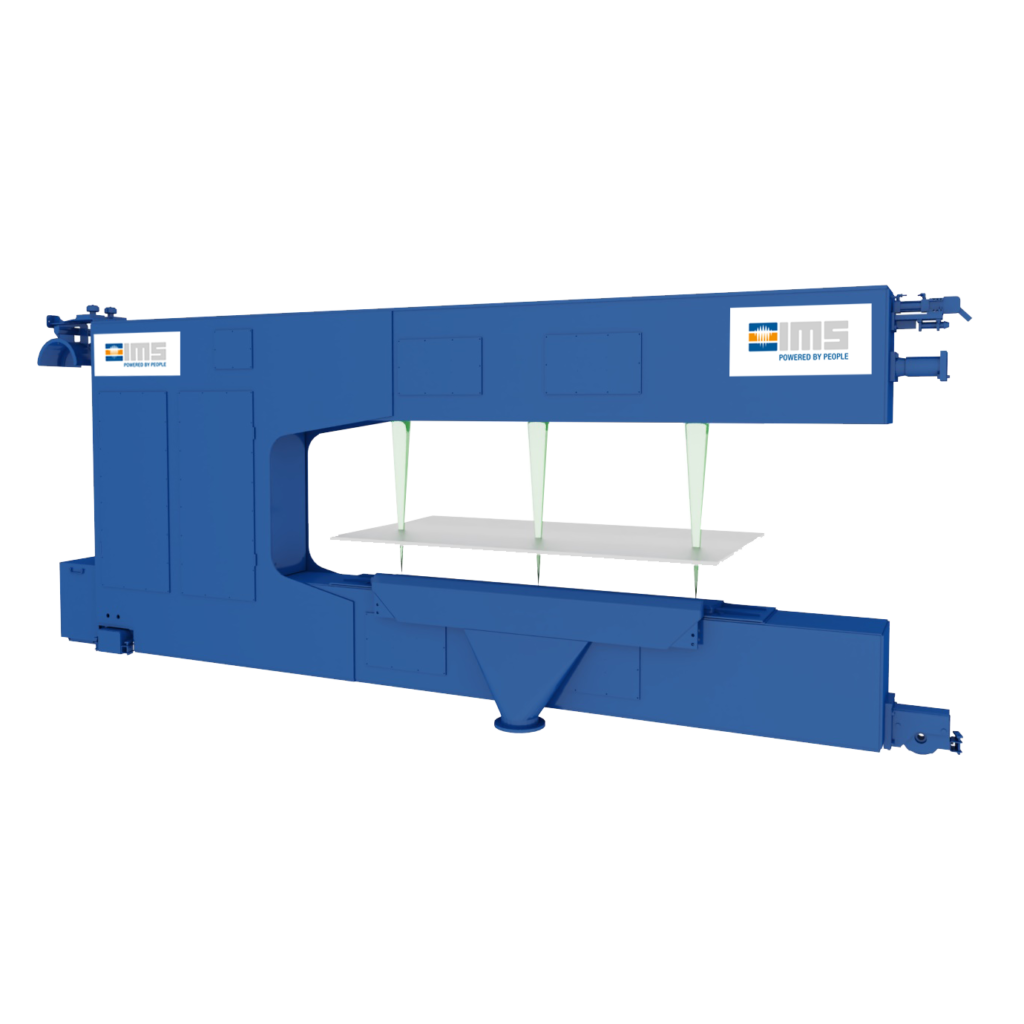

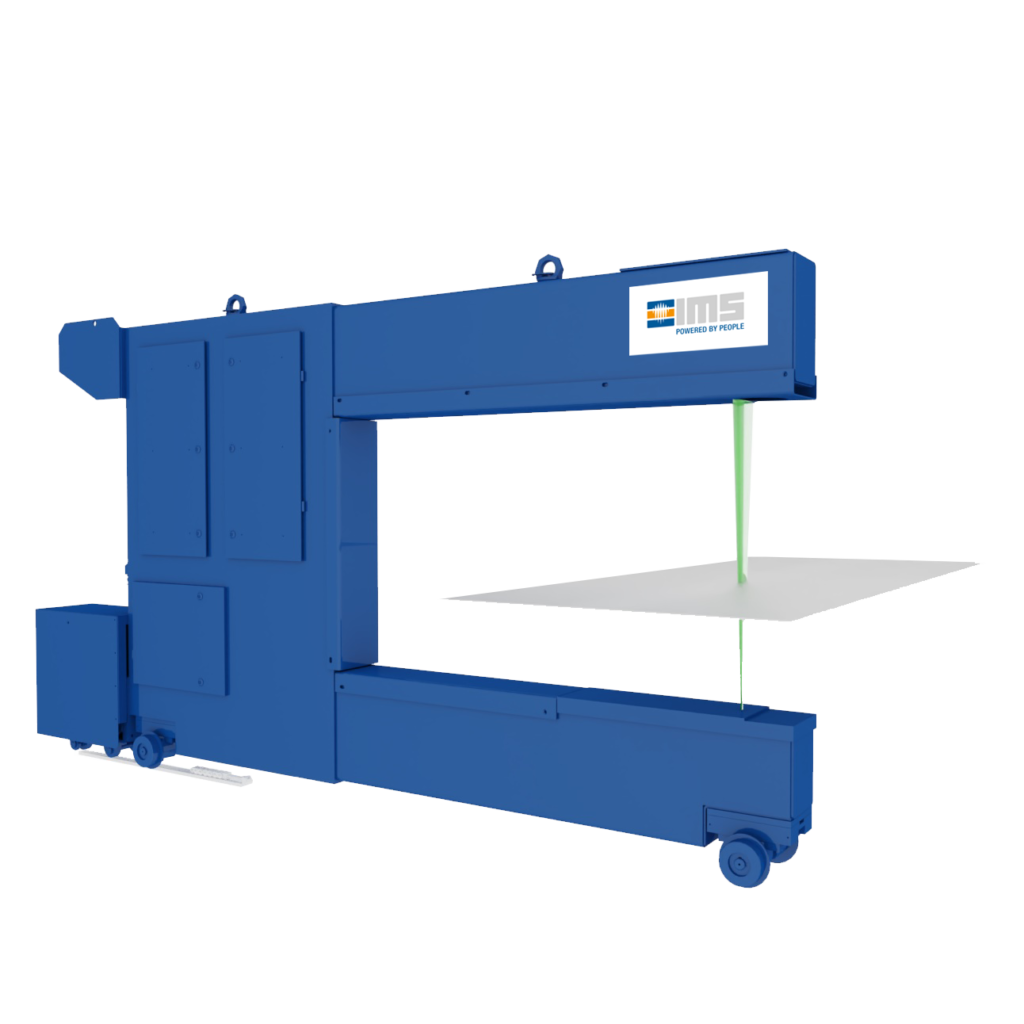

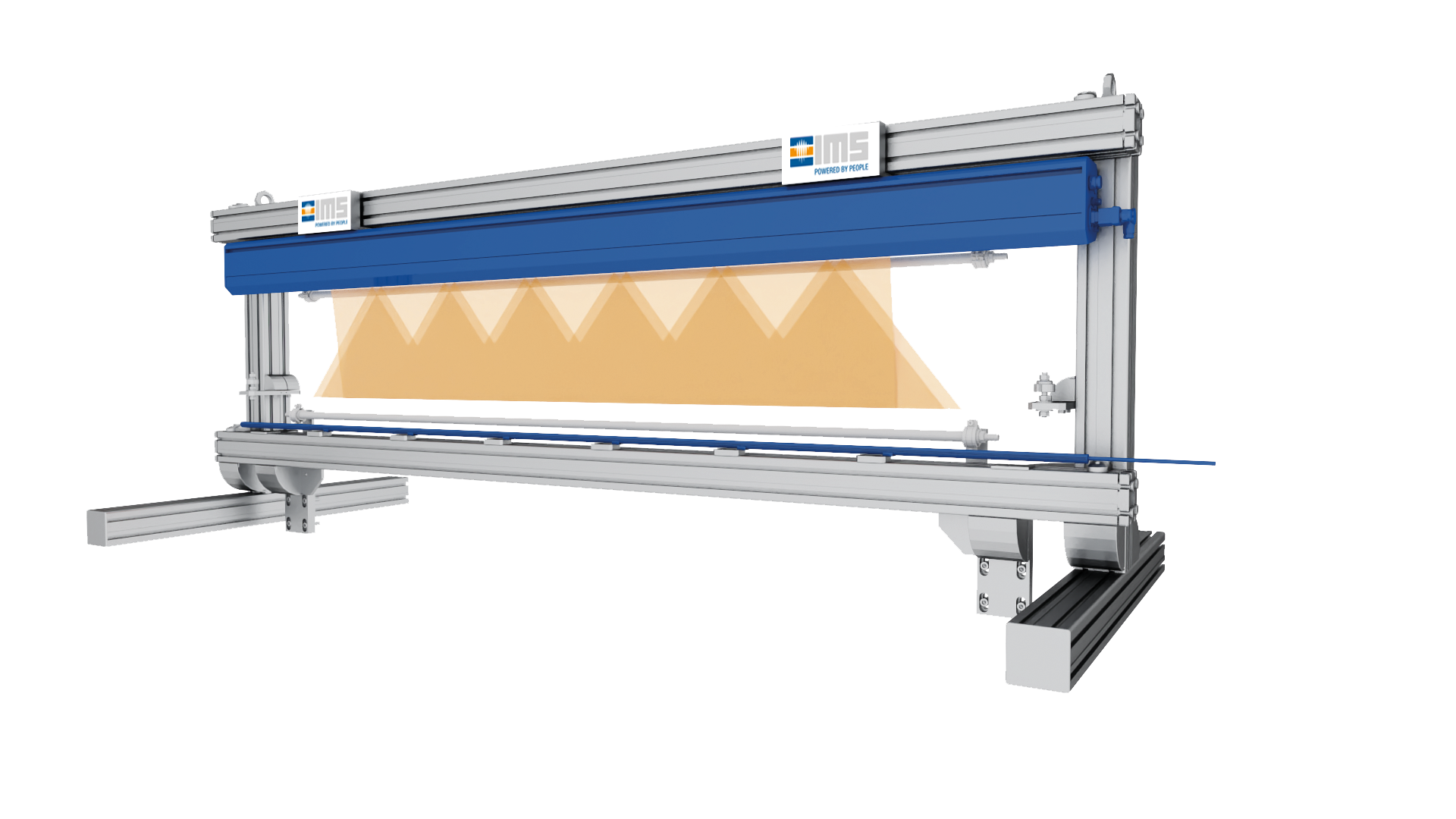

Non-retractable Gauge (Foil Mill)

XR Centreline Thickness Measuring System

XR Centreline Thickness Measuring System

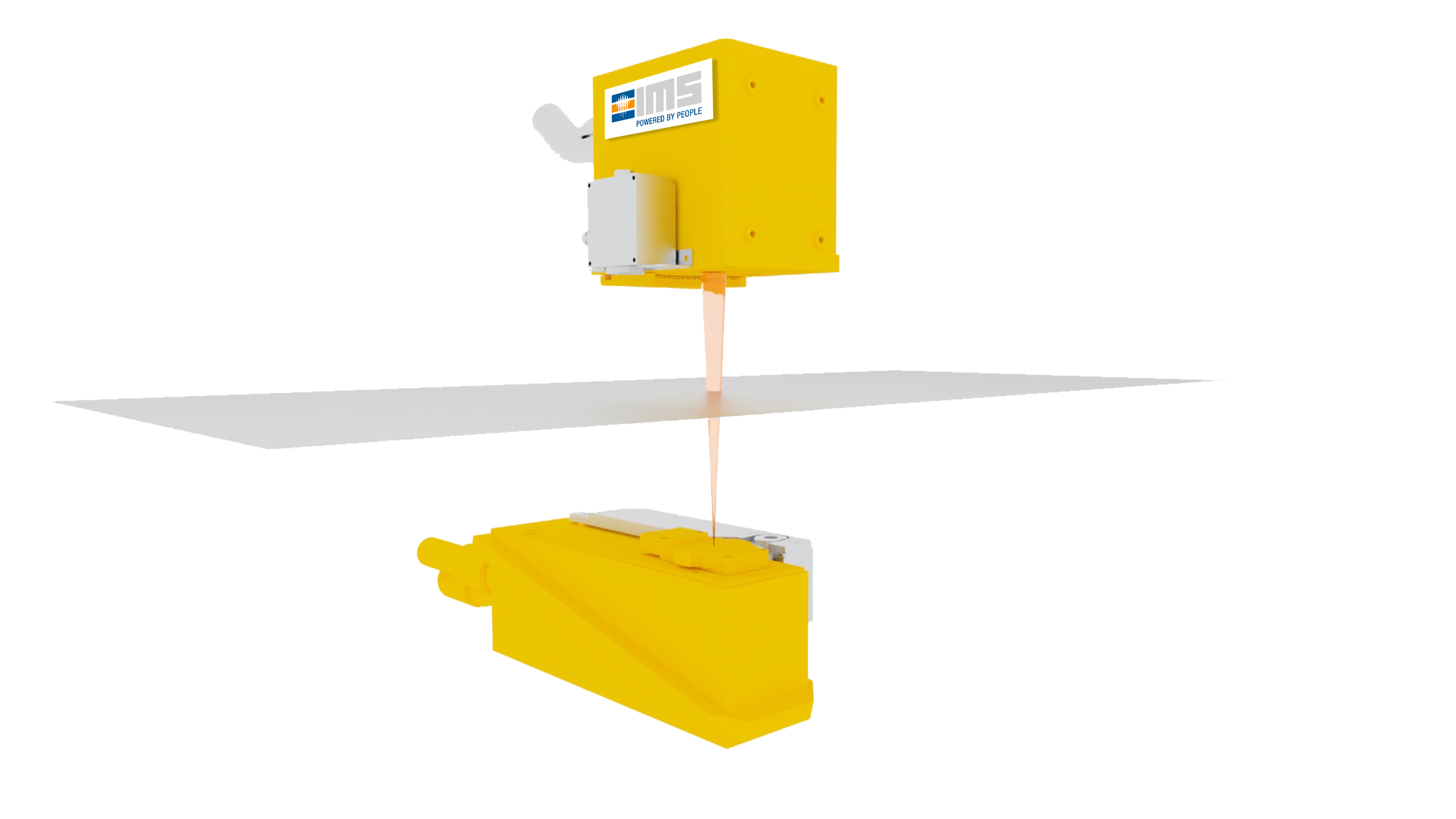

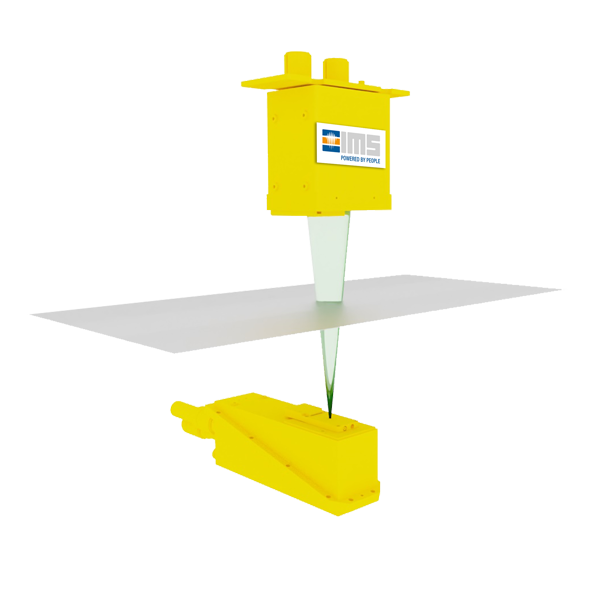

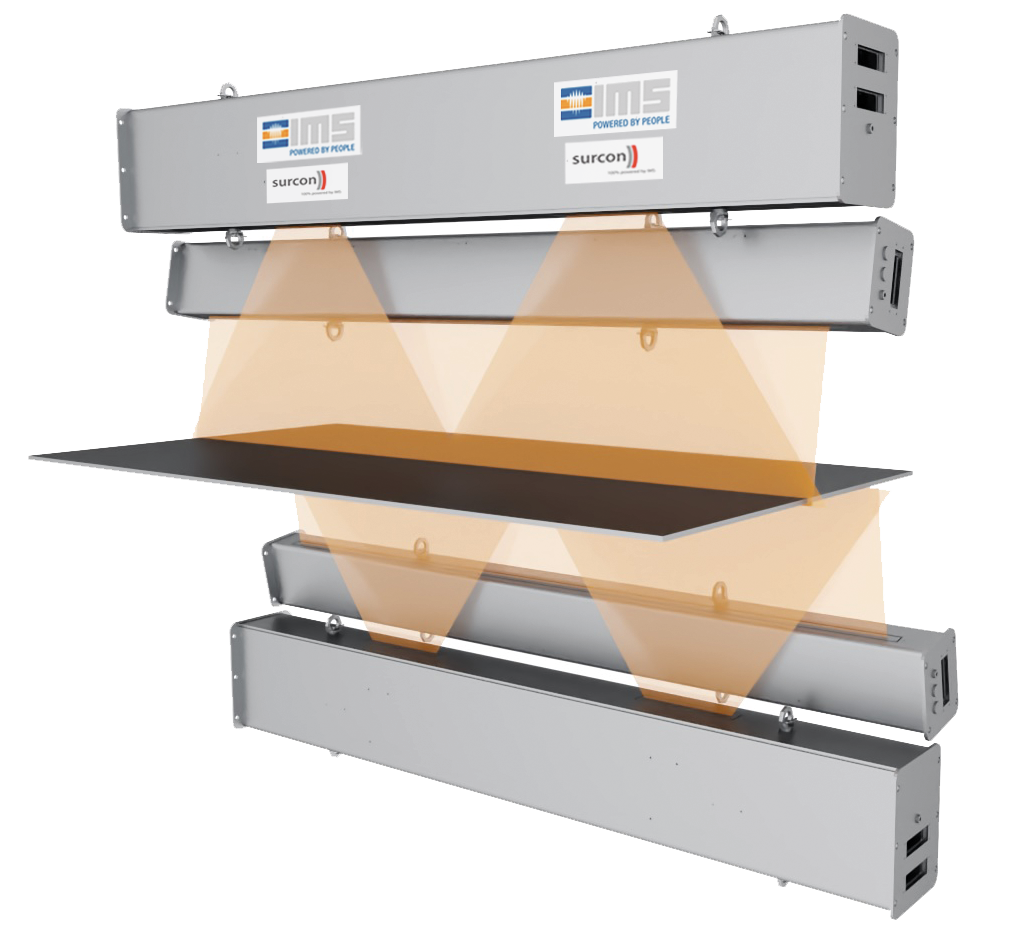

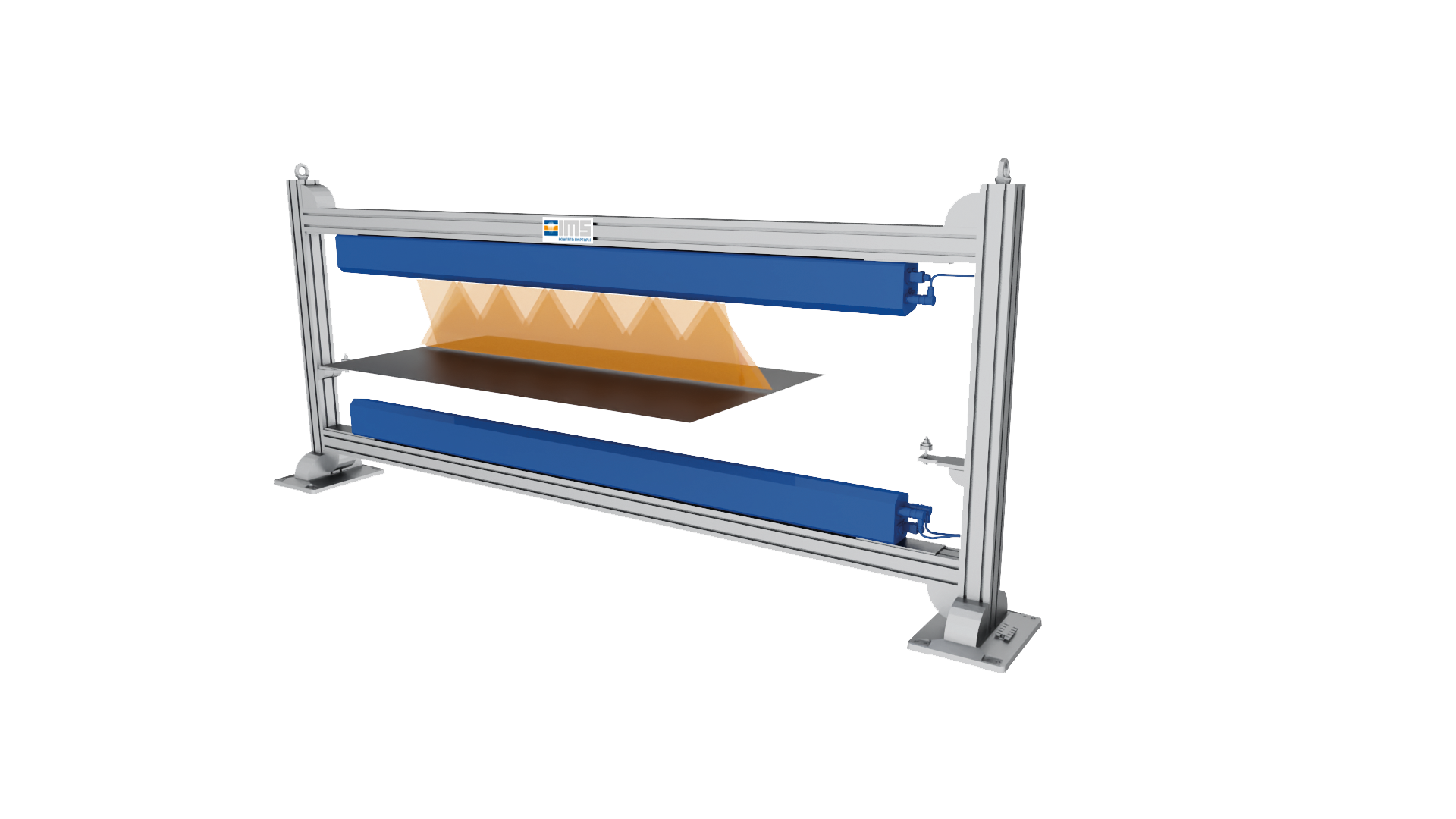

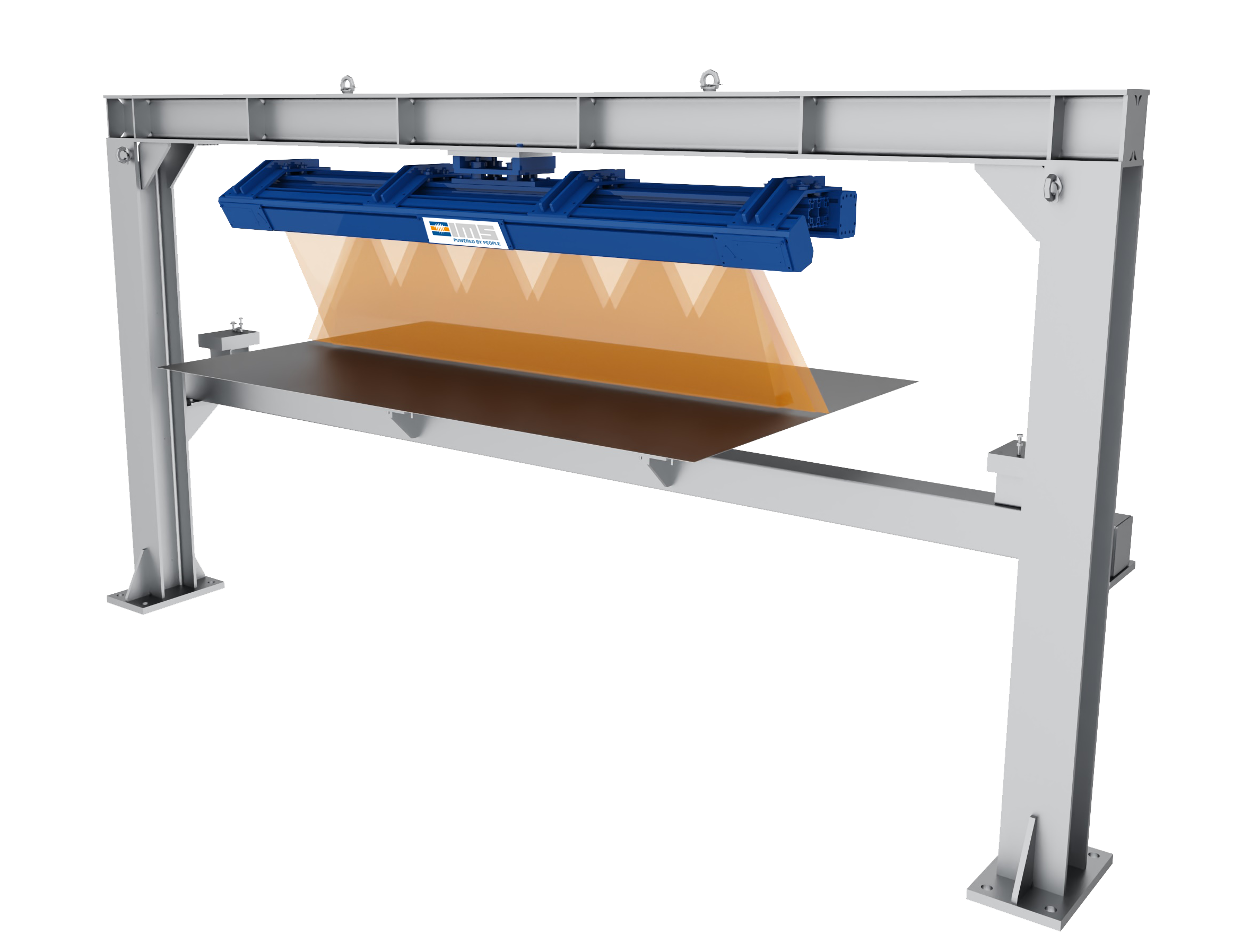

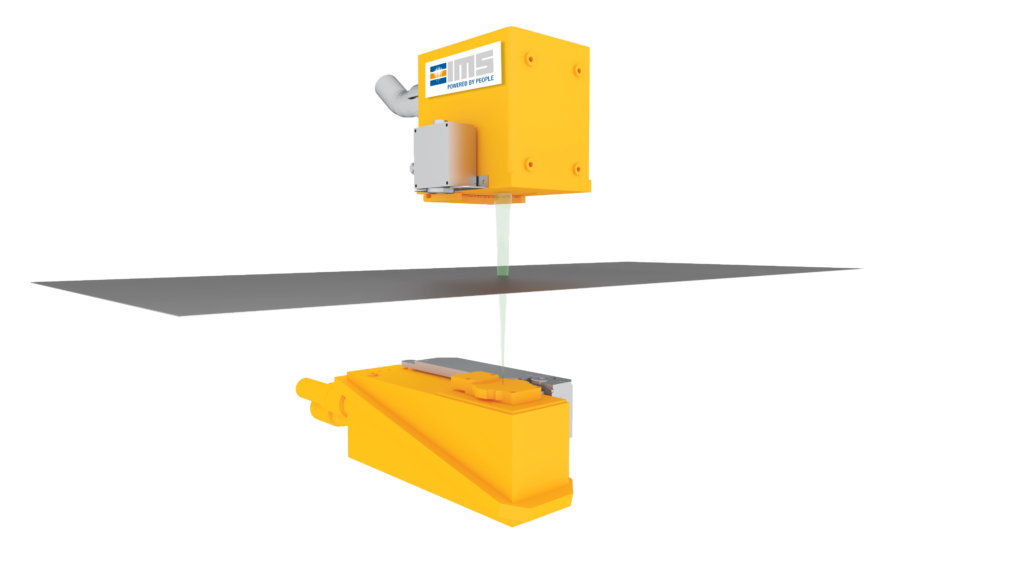

By means of continuous, non-contact, real-time measurement, the XR thickness measuring system measures the centreline thickness of the foil.

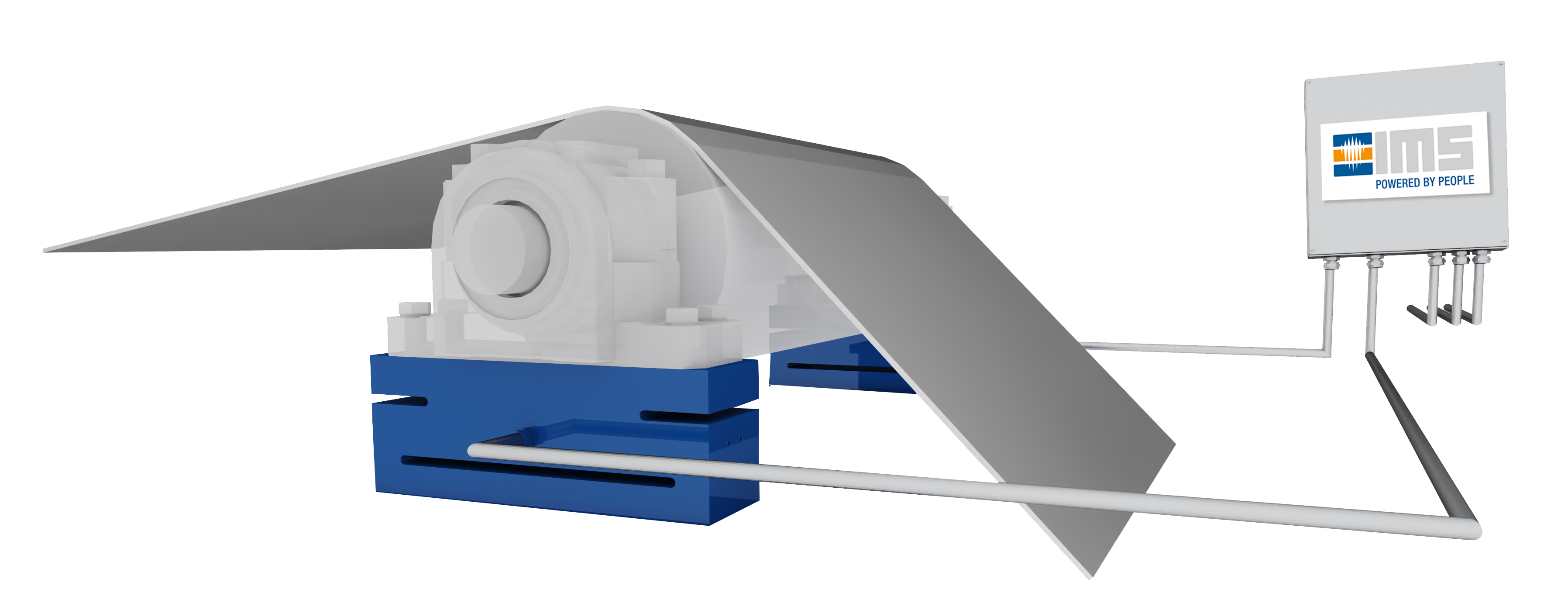

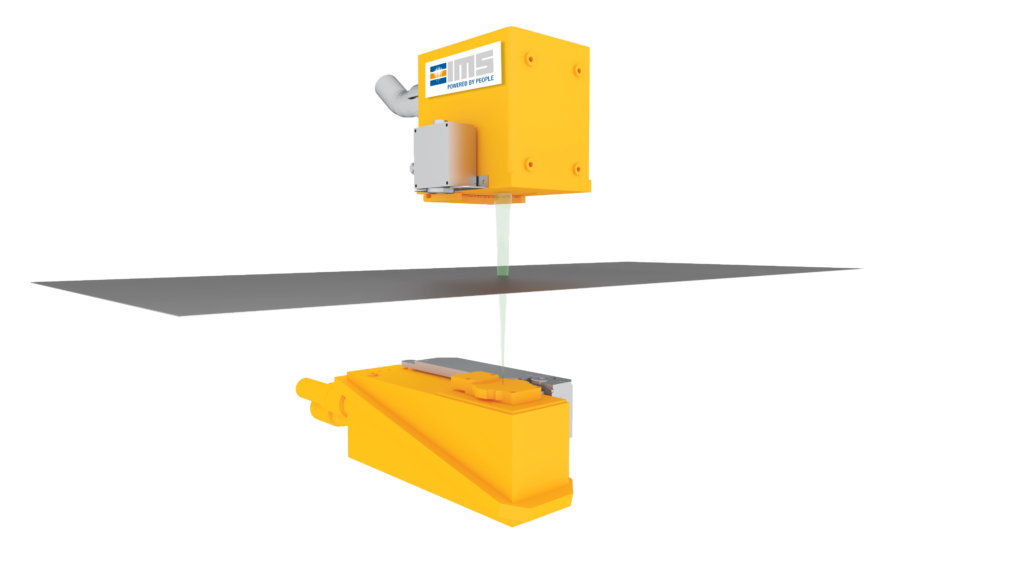

With this measuring method, the material is radiated by a single x-ray source, mounted in the lower housing of the gauge.

One or three ionisation chambers, installed in the upper housing of the gauge, receive and convert the remaining radiation into electrical signals. Further realtime processing calculates the accurate thickness of the foil.

centreline thickness measurement

optional:

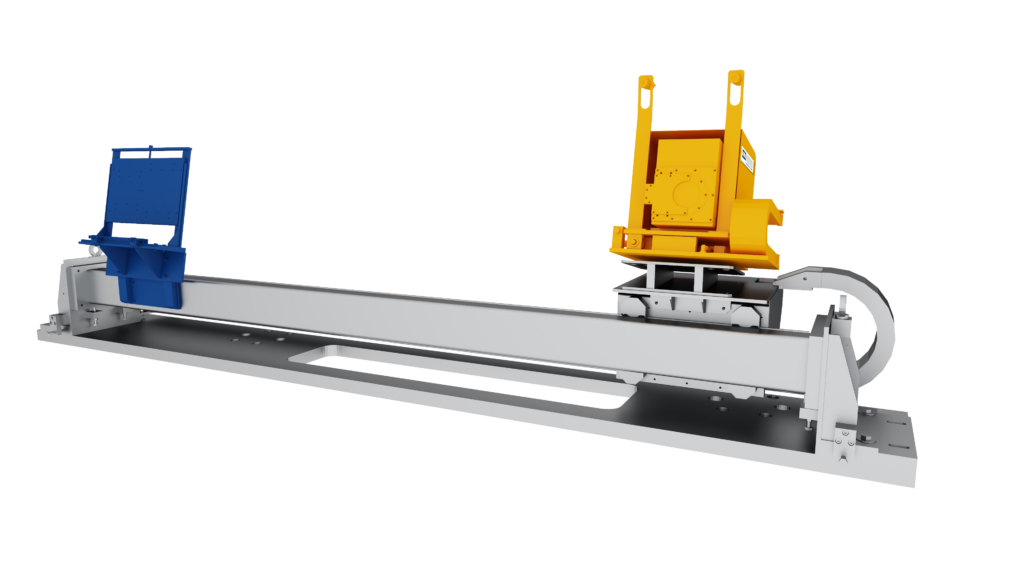

– fixed mounted non-retractable C-frame

– swivel mechanism for the detector head

Special Features

- customised design and software

- automatic calculation of alloy correction

- remote maintainability

- key components, such as measuring transducer, compact x-ray generator incl. x-ray control unit and ionisation chambers (detectors) are developed and manufactured by IMS Messsysteme GmbH, Germany

-

compact x-ray generator incl. x-ray control unit:

- high shock and vibration resistance

- maintenance-free / low-maintenance high-voltage connectors

- easy to maintain

-

detectors (ionisation chambers):

- pluggable

- no cooling required

- very long lifetime

- highest signal stability

- maintenance-free -

X-ray source (metal-ceramic tubes):

- operated at a constant high voltage level, no standard magazines

- large difference between maximum and operational load (very long lifetime)

do you have any questions?

#IMS Expert

Christian Knackstedt,

Dipl. Engineer

…for you as a specialist for cold rolling mills. One part of your solution here is offered by our innovative and high-precision measuring systems for the cold strip sector, which have proven that they measure and detect lastingly and reliably even under the most adverse environmental conditions.

How challenging and different such environmental conditions as well as the tasks assigned to you as the responsible person can be is something I am well aware of, not only theoretically but also practically, from more than 20 years of working for IMS. I started out as a systems engineer in the field of software and commissioning. Today, in the position of Global Sales Manager, I am your IMS expert for measuring systems in the cold strip sector.

Making measurable what can be measured is part of our corporate philosophy. The “how” in your particular case is as much my challenge from the moment you contact me as it is yours. My personal benchmark is your constant high product quality and – especially – your equally constant trust out of conviction in the performance of our measuring systems.”

Reserve your personal consultation appointment now!

Choose between a scheduled call back, a Teams video conference or simply use our contact form.

We look forward to hearing from you!

Non-retractable Gauge (Foil Mill)

XR Centreline Thickness Measuring System

XR Centreline Thickness Measuring System

Technical Information

Material data (typical for foil mills)

Typical thickness range:

0.012 to 0.4 mm, but not limited to

Speed:

2,200 m/min, but not limited to

Width:

2,000 mm, but not limited to

Measurement system data

Gauge type:

fixed mounted, non-traversable measuring point

Radiation source:

X-ray tube (metal-ceramic)

Measuring dynamics

Analogue time constant:

5 ms

Total time constant:

5 ms or 10 ms

Cycle time data output:

2 ms

Measuring accuracy (2 sigma values)

Linearity:

0.05 %, not better than ±0.075 μm

Long term drift (10 hrs):

0.1 %, not better than ±0.10 μm

Reproducibility:

0.1 %, not better than ±0.10 μm

Statistical noise (10 ms):

0.1 %, not better than ±0.10 μm

Measure.Inspect.Detect.

Product Catalogue for Aluminium Rolling Mills

- Learn more about the product portfolio of our high-precision measuring systems for aluminium hot strip rolling mills and cold strip rolling mills

- Standard systems for measurement and detection of slab dimension, thickness, thickness profile, length, width, temperature, speed, 2D surface inspection as well as various special systems

- Special designs possible on customer request

IMS Measuring Systems for Aluminium Cold Rolling Mills

(Aluminium Hot Rolling Mills)

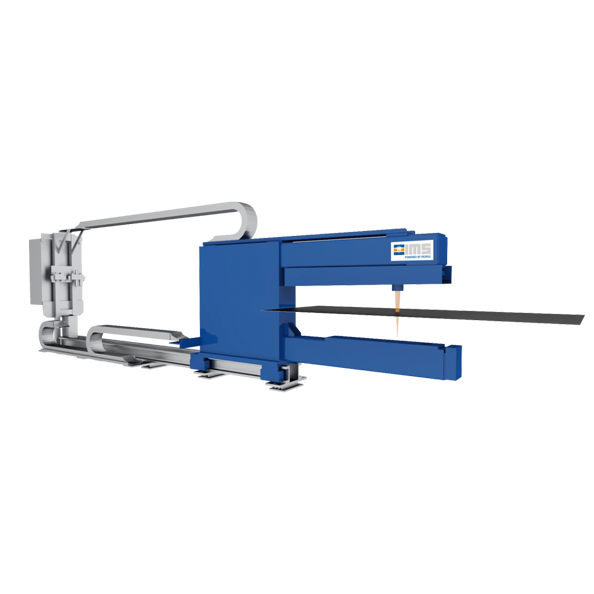

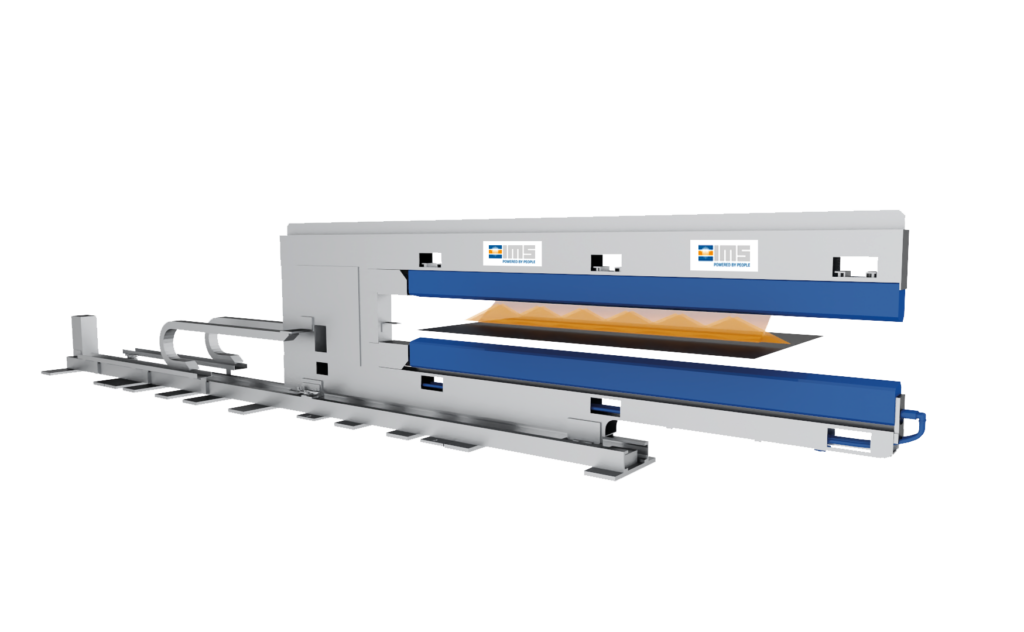

XR Traversing Thickness Profile Measuring System

(Aluminium Hot Rolling Mills)

XR Traversing Thickness Profile Measuring System (cold rolling mill)

(Aluminium Cold Rolling Mills)

(Aluminium Cold Rolling Mills)

(Aluminium Cold Rolling Mills)

(Aluminium Cold Rolling Mills)