Surcon 2D

Surface Inspection System

Surface Inspection System

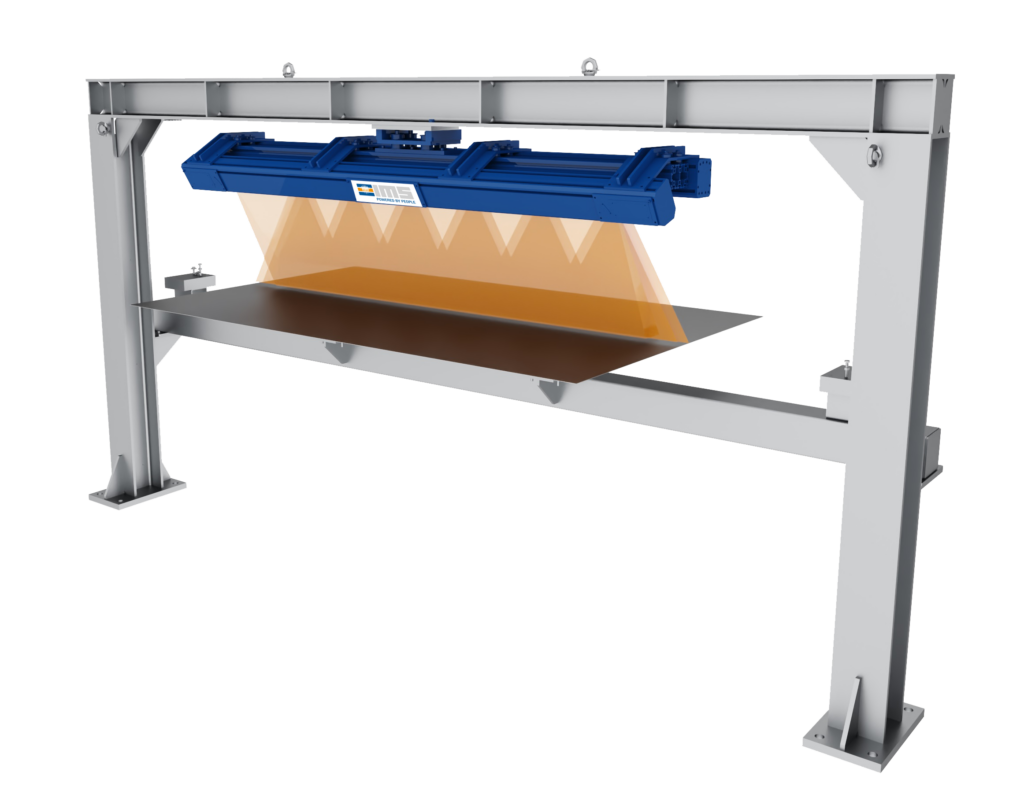

Surcon 2D surface inspection systems inspect and visualise even the smallest defects and anomalies as online inspection systems. They impress with a synergy of decades of expertise in the development of precision measuring systems, combined with high-end technical surface inspection.

Surface inspection of even the smallest defects is thus possible under even the most difficult conditions such as confined spaces, acidic vapours or oils.

In addition, a powerful, intuitive HMI ensures that the most relevant measurement results are always available.

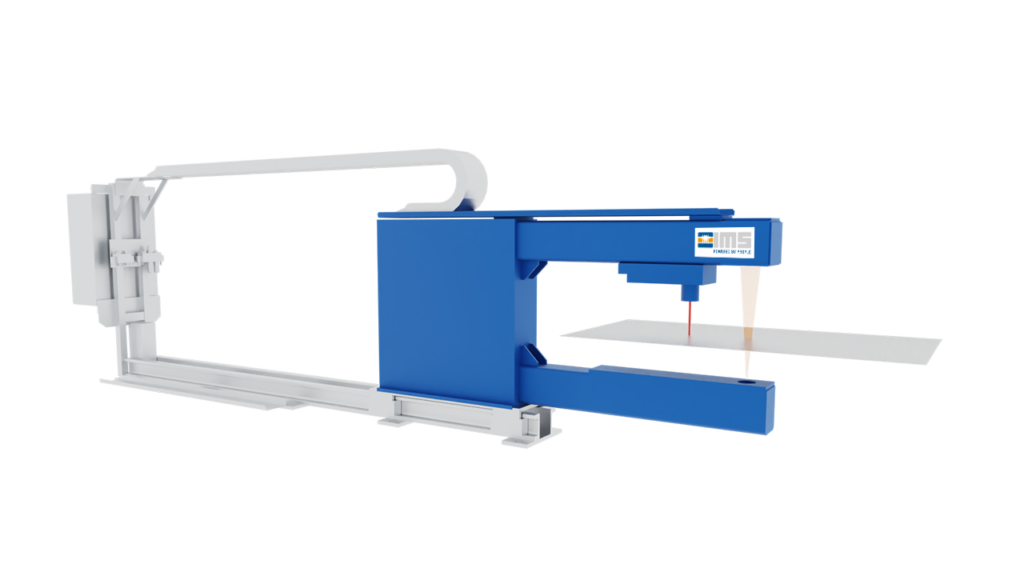

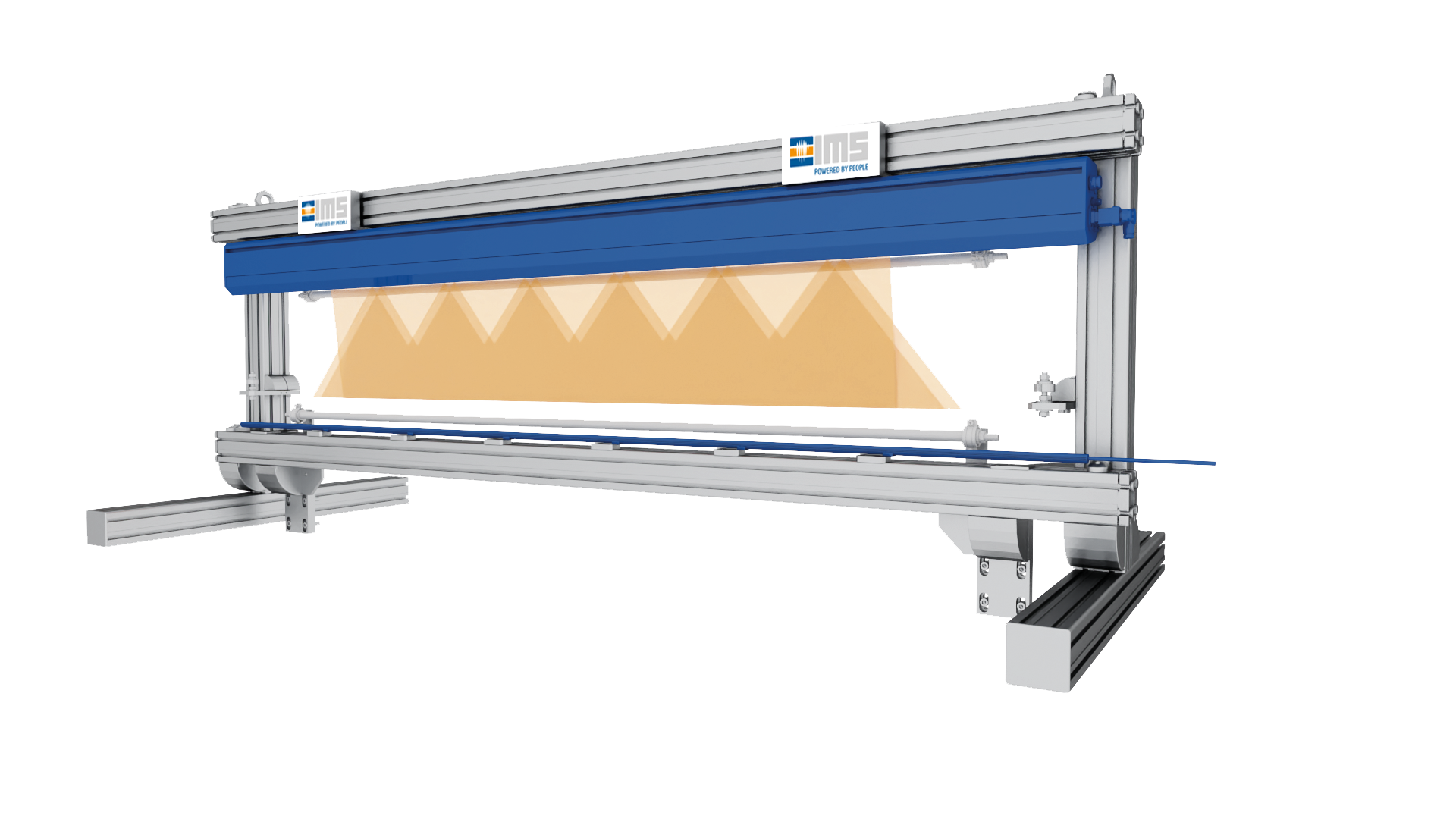

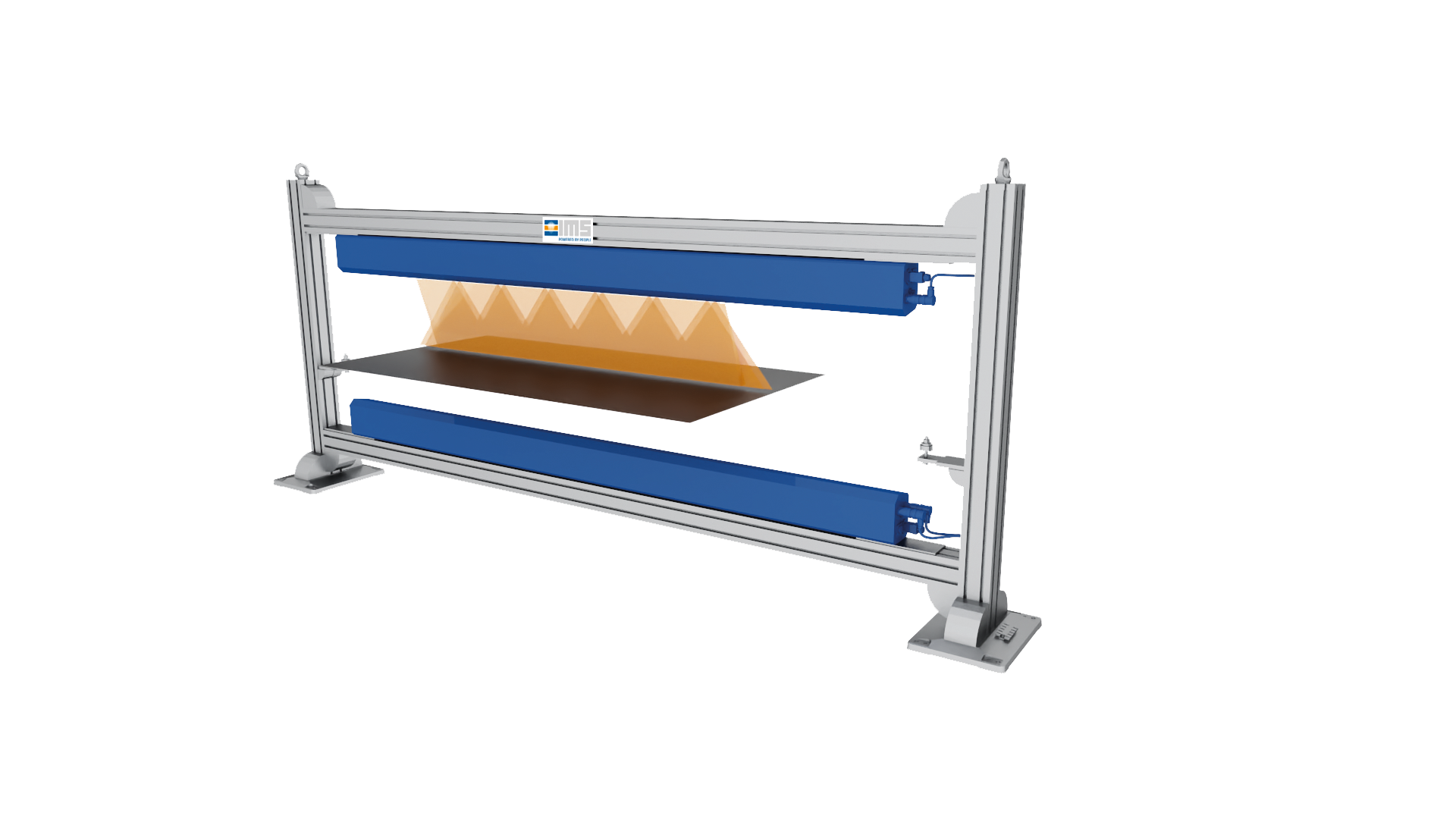

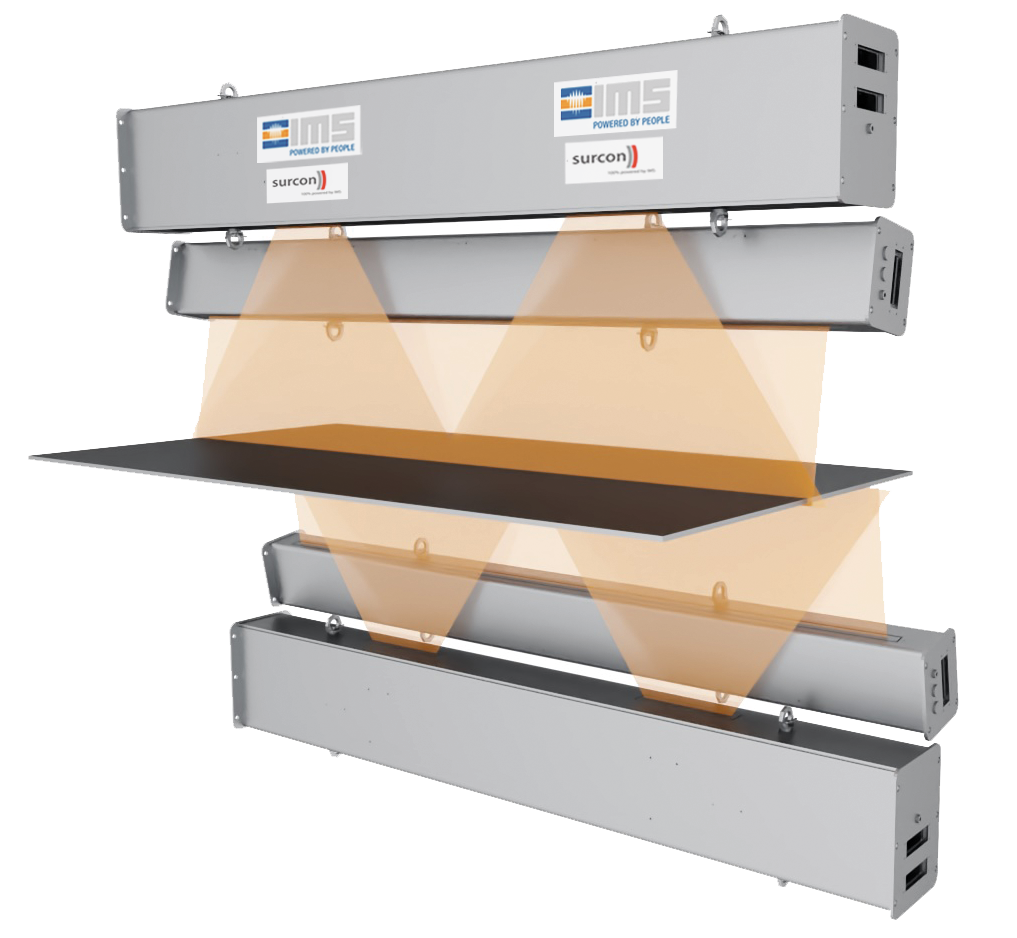

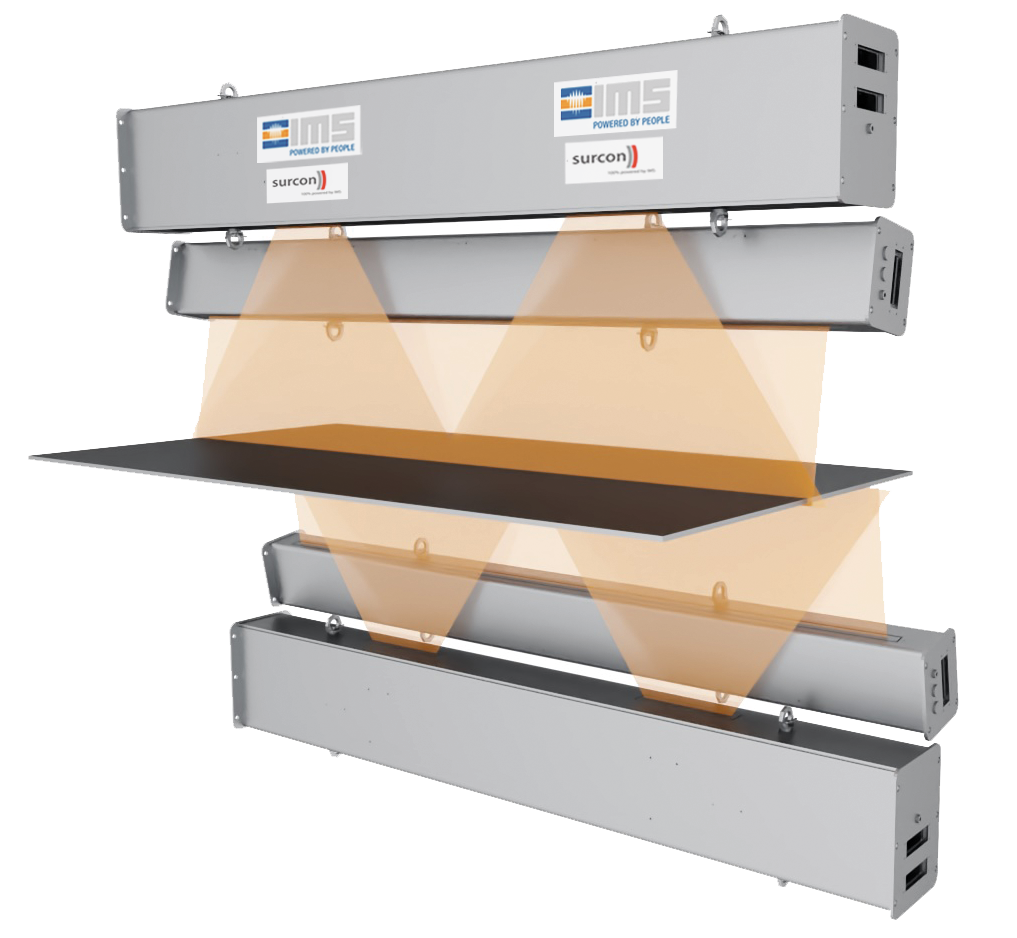

100% online inspection using fast line scan camera

and high-power LED

automated defect detection and classification

instant detection of periodic defects that indicate roll damages

Special Features

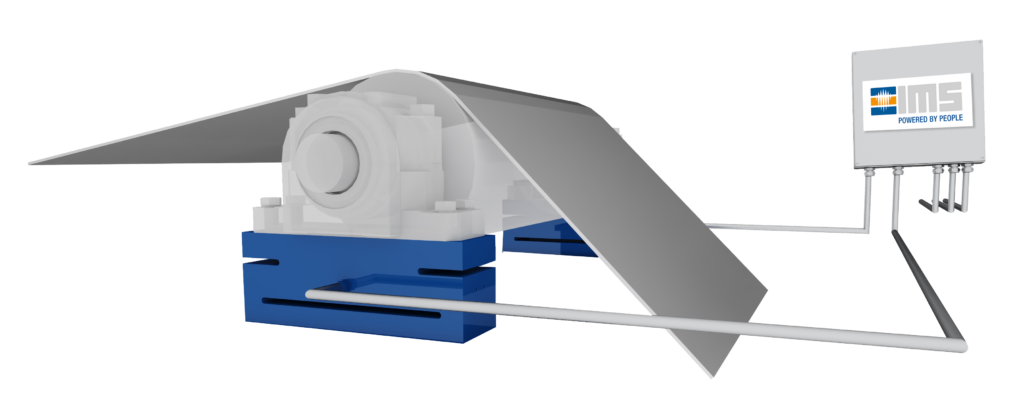

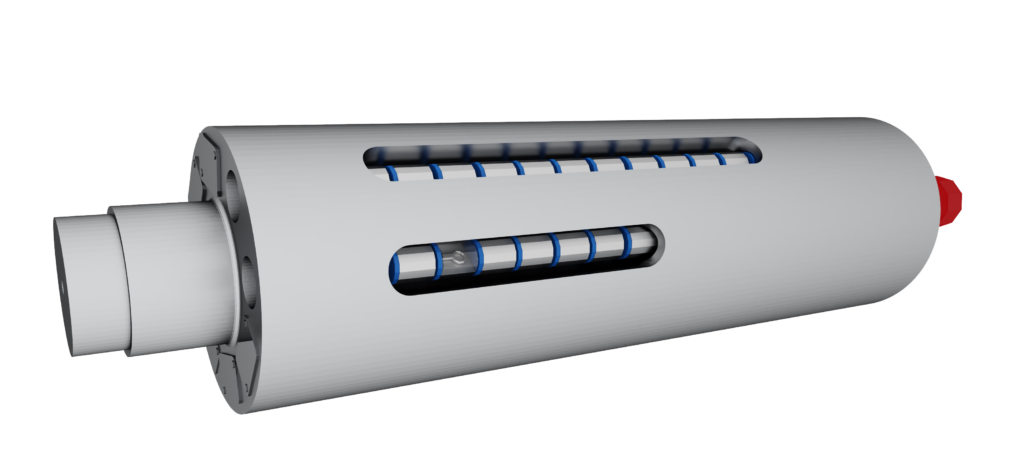

- reliable IMS hardware and housing with integrated cooling ensures a long-lasting and low-maintenance operation

- customised solutions and individual adaptation to local conditions

- optional, integrated blower to protect the system from dust, dirt and splash water and to reduce maintenance requirements

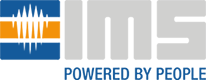

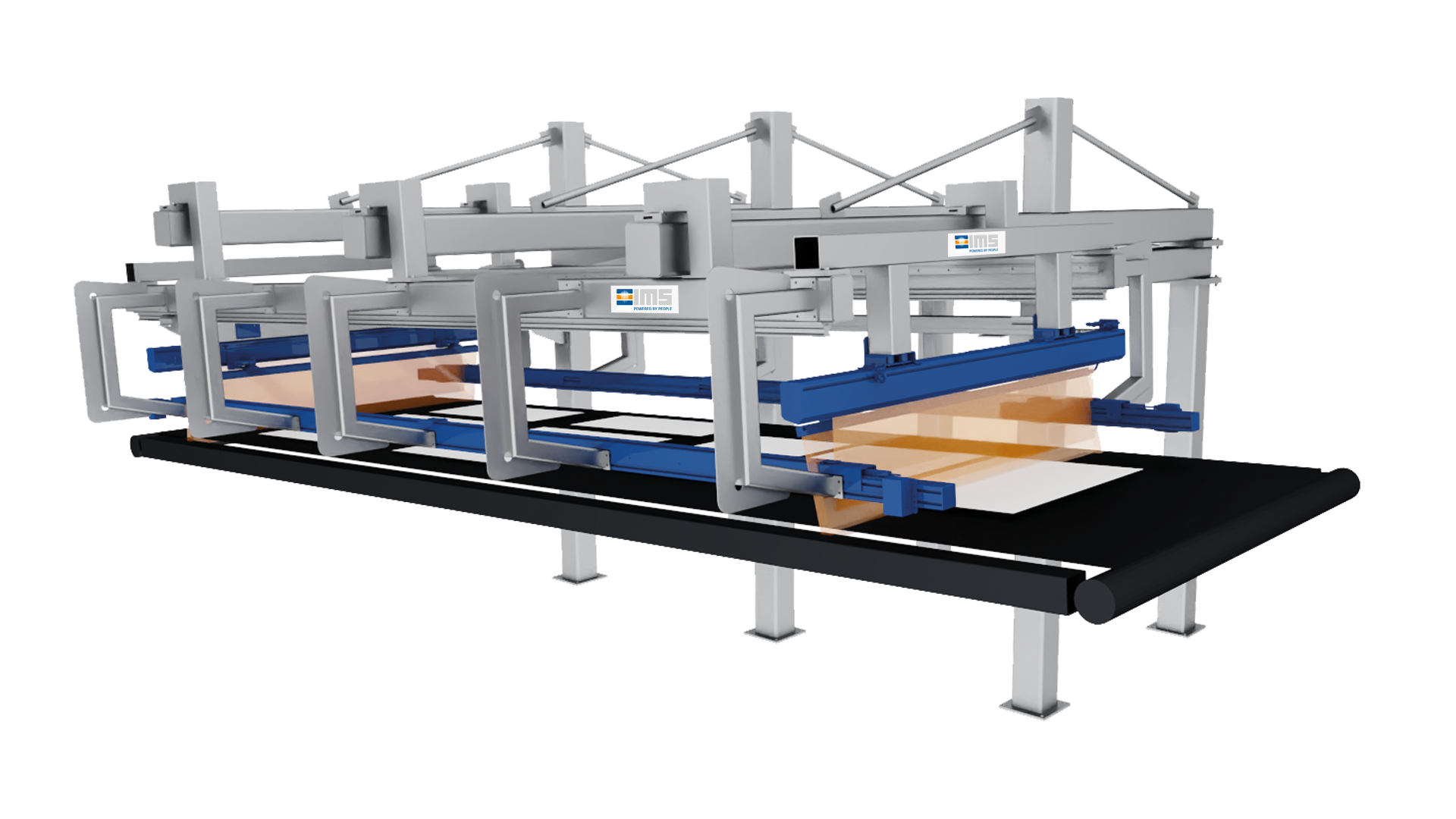

- optionally available as C-frame for maximum convenience and easy maintenance in service position

- powerful toolsets for performance optimisation and data analysis

- apply surface inspection to each processing step for conclusive root cause analysis

- online visualisation of results and report generation via customised results interface

- integrated quality assessment tool – create your own rules for instant results evaluation

Reserve your personal consultation appointment now!

Choose between a scheduled call back, a Teams video conference or simply use our contact form.

We look forward to hearing from you!

Surcon 2D

Surface Inspection System

Surface Inspection System

Technical Information

Material Data

Max. speed:

up to 1,900 m/min for 0.4 mm length resolution

Width:

not limited to

Length:

no restriction / continuous inspection possible

Measurement System Data

Configuration:

2D bright field

Installation type:

fixed installation

Camera type:

CMOS line scan camera / Gigabit Ethernet / Camera Link

Illumination source:

High Power LED 450 nm / 630 nm / white

more than 500 W/m² at 500 mm working distance

Typical working distance:

400-1,500 mm

Performance Data

Chip size / framerate:

up to 8,192 pixels / up to 140 kHz

Typical resolution:

0.2 mm x 0.2 mm / 0.2 mm x 0.4 mm

Image storage:

defective areas in full resolution

full background in reduced resolution

short intervals can be stored in full resolution

Image storage capacity:

typical 60 TB

Image type:

open, lossless compressed tiff format

Database:

Microsoft SQL Server

Evaluation

Classification:

feature based, pre-trained AI

parallel classification using multiple classifiers

Features for classification:

> 400 feature values per defect

Quality management:

rule based quality grading

Measure.Inspect.Detect.

Product Catalogue for Metal Service Centres

- Learn more about the product portfolio of our high-precision measuring systems for metal service centres

- Standard systems for measurement and detection of thickness, width, slit strip width, sheet geometry, holes, pinholes, flatness, evenness, edgecracks, surface inspection, strip tension, web tension as well as various special systems

- Special designs possible on customer request

IMS Measuring Systems for Metal Service Centres

XR Traversing Thickness Profile Measuring System

(Metal Service Centres)