Kr

Coating Weight

Measuring System

Coating Weight

Measuring System

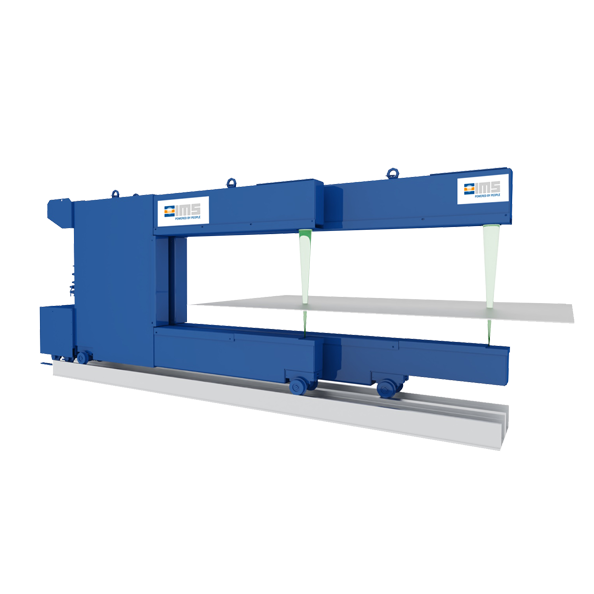

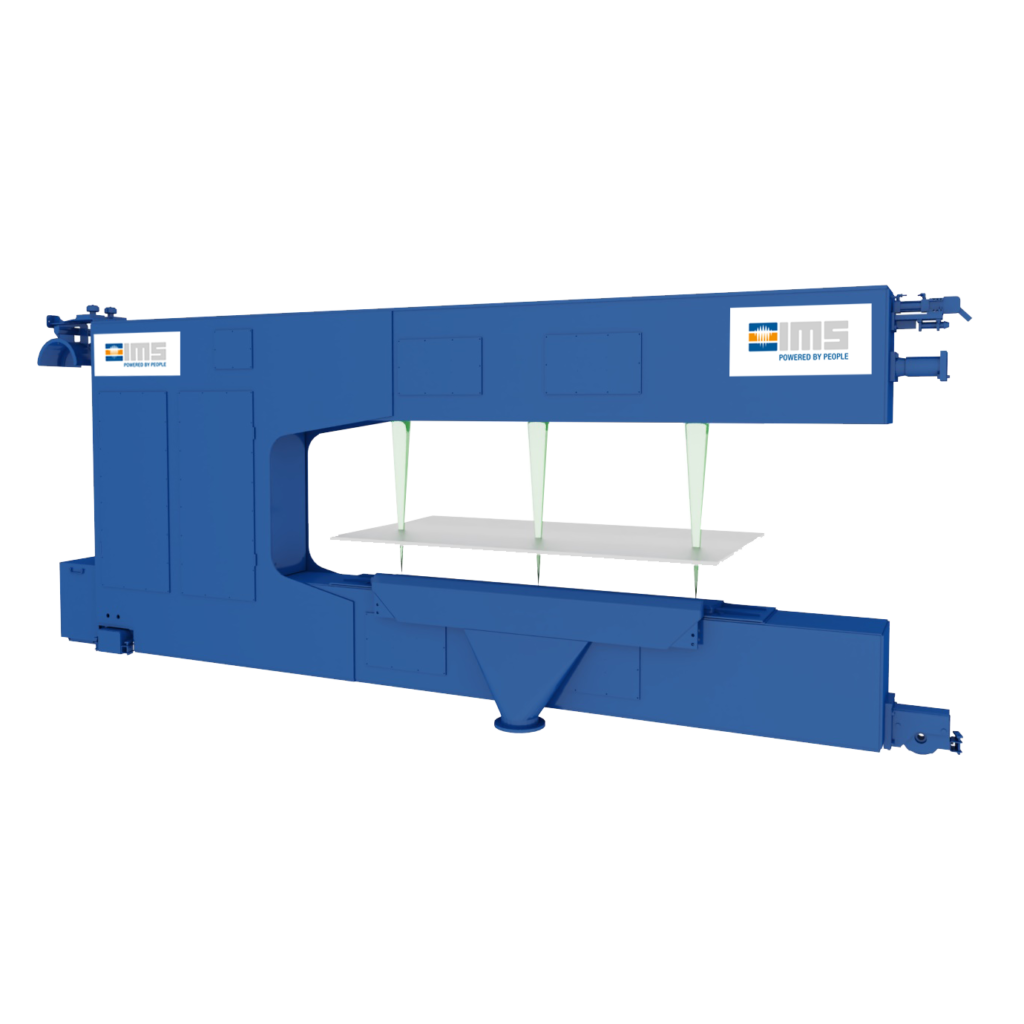

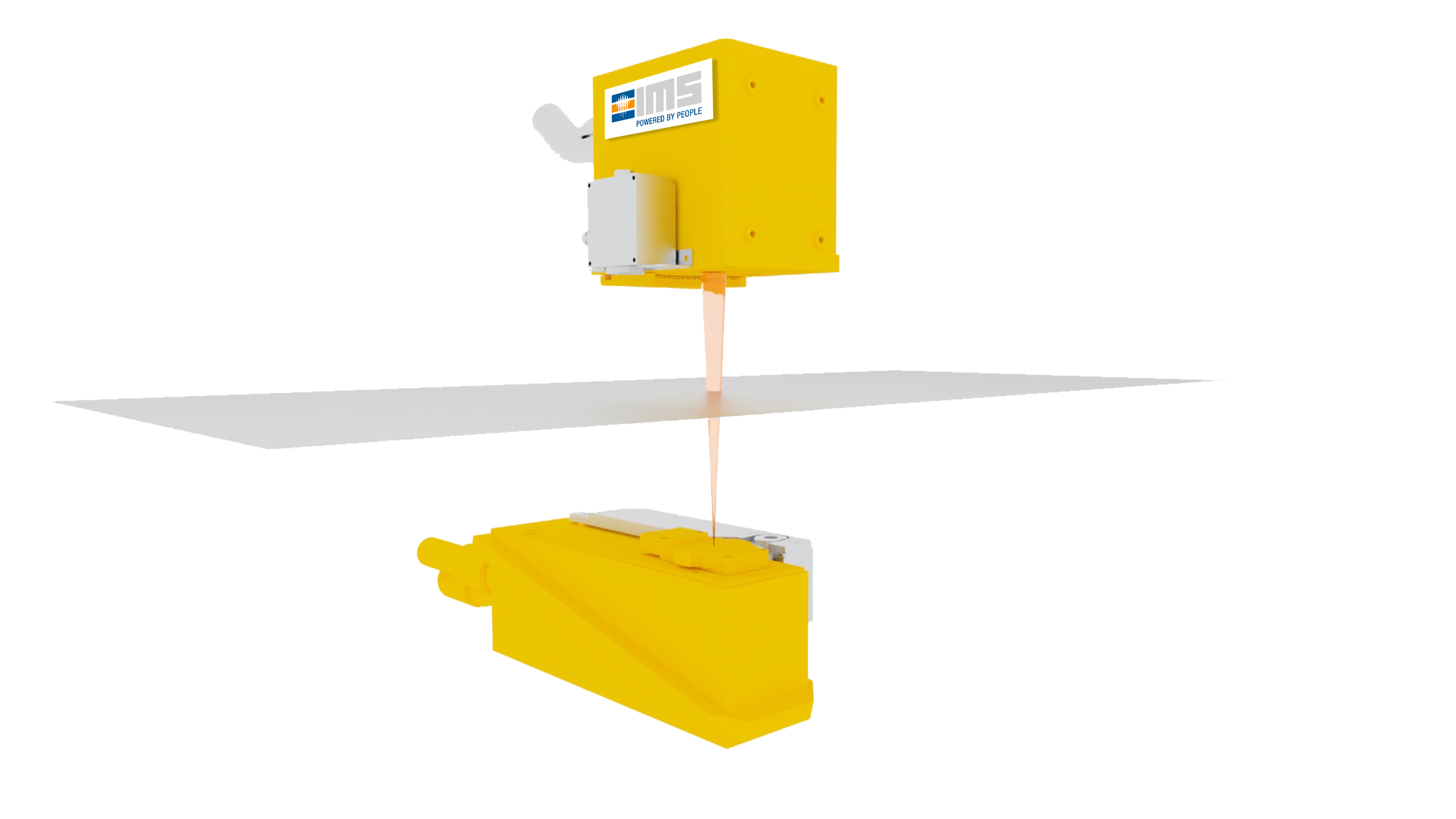

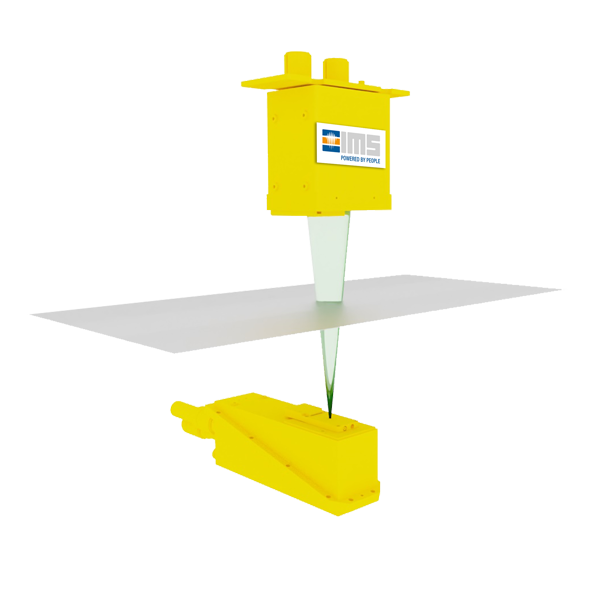

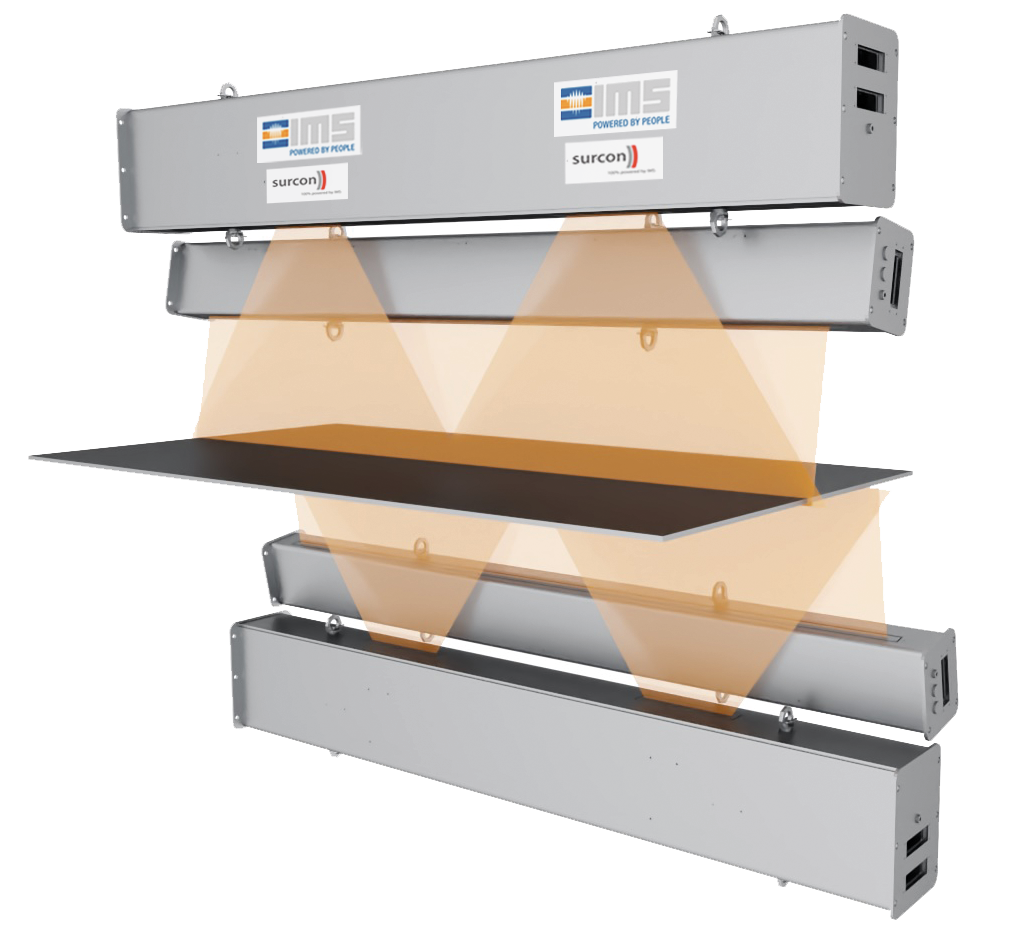

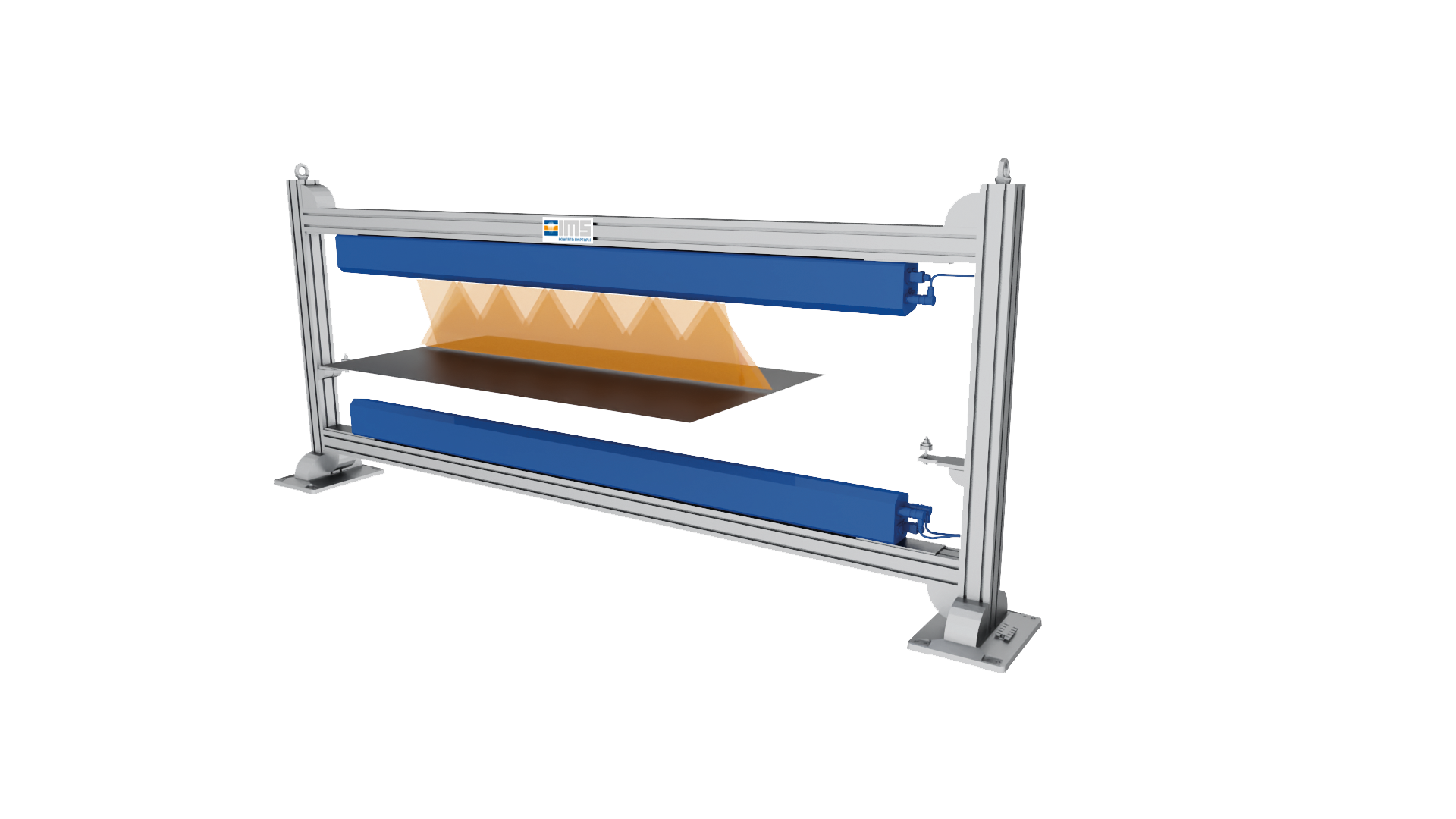

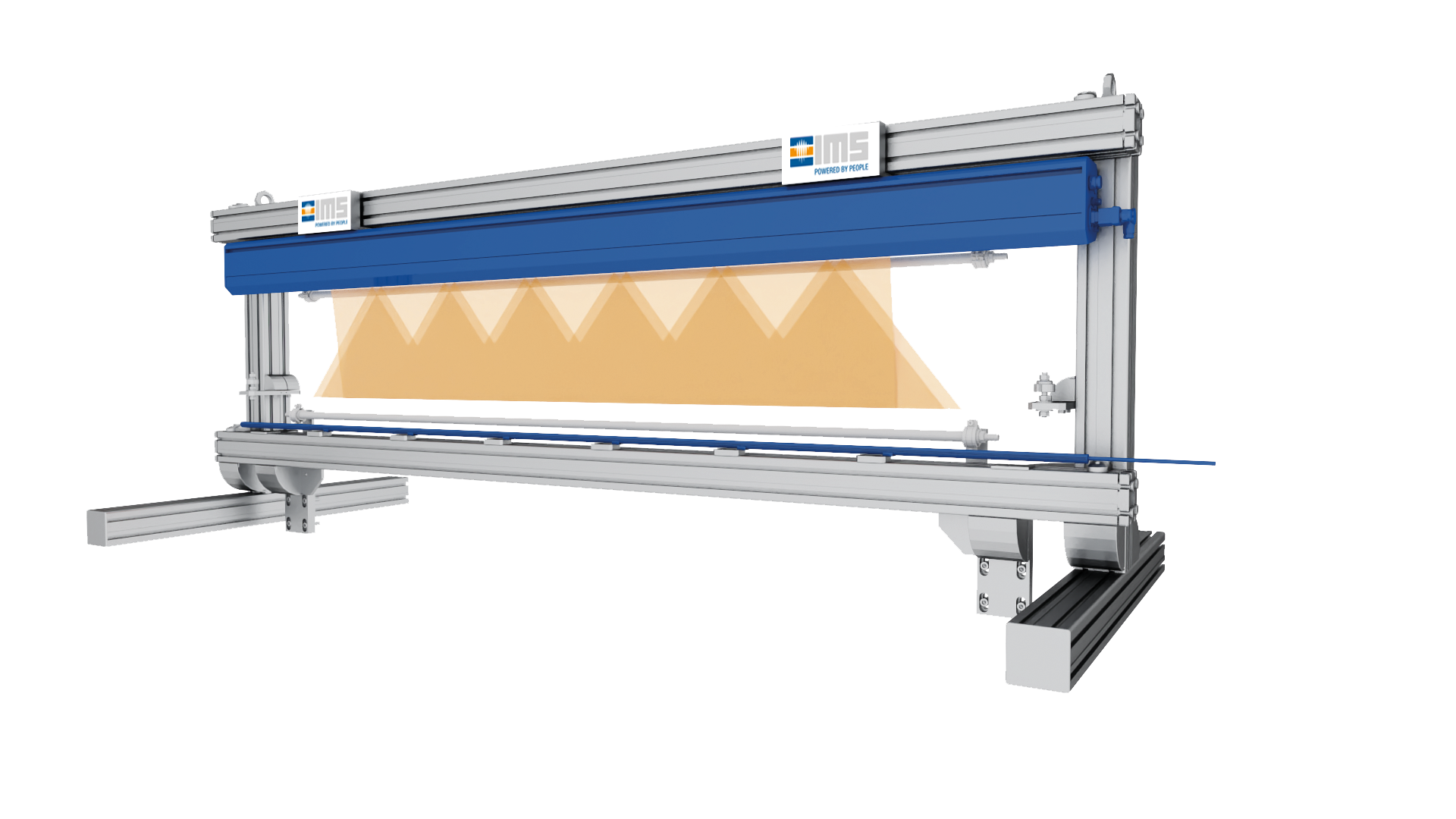

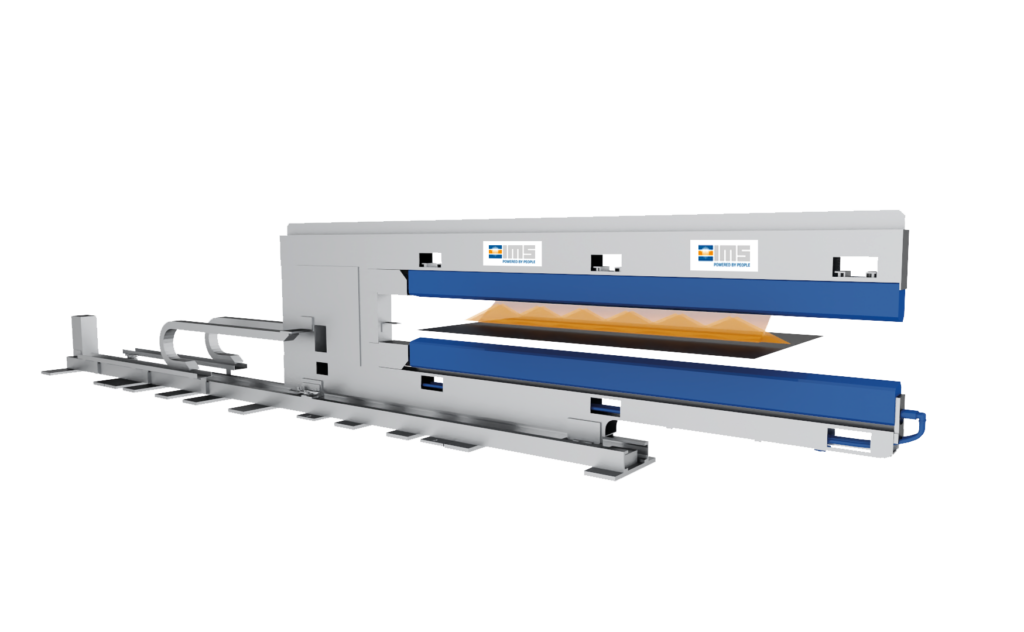

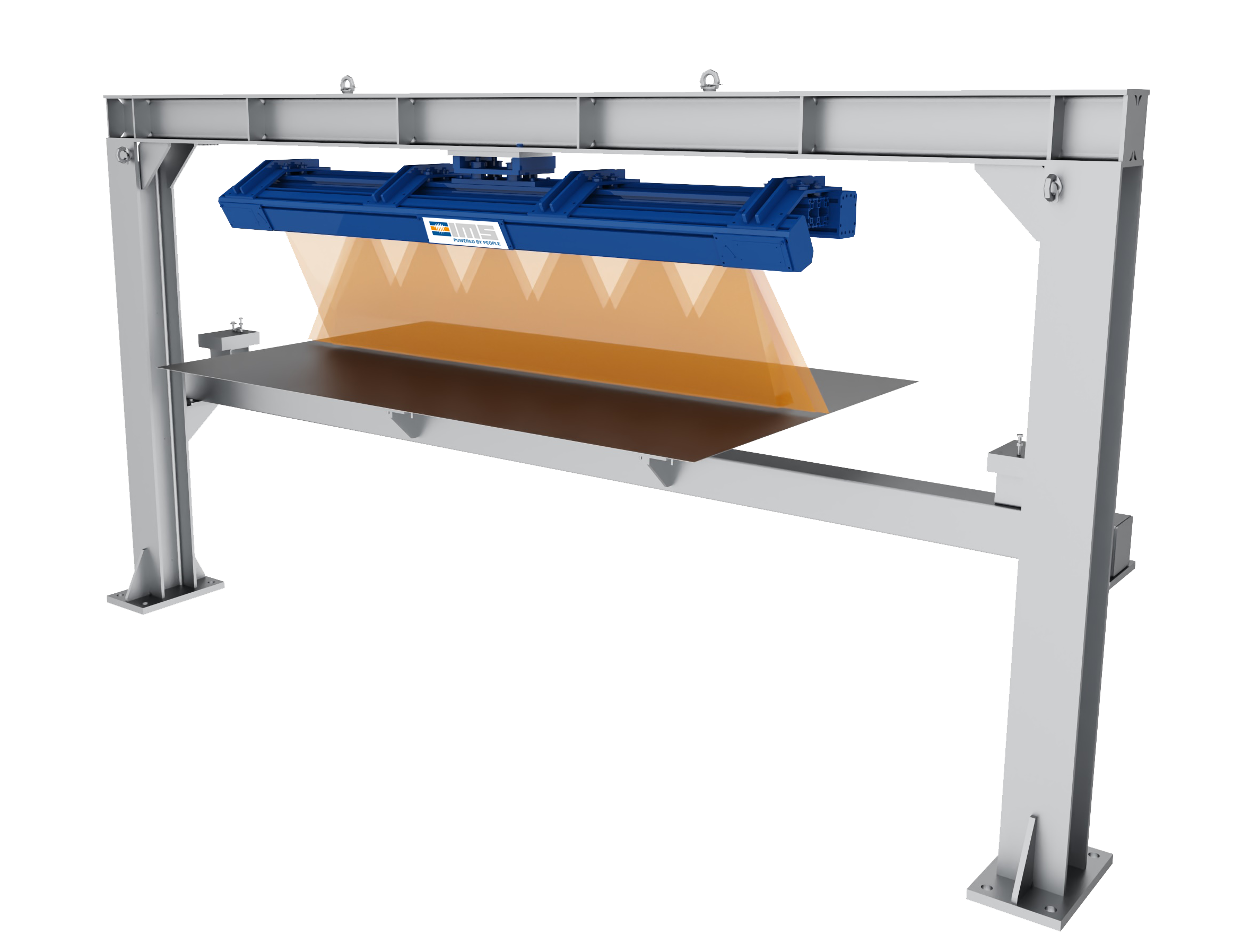

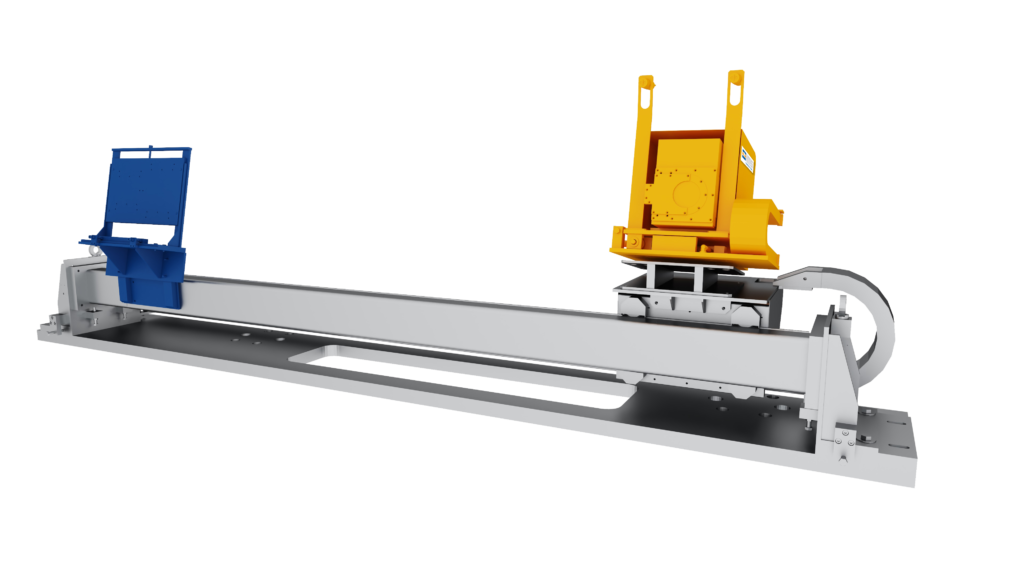

The Kr Coating Weight Measuring System is used for continuous, non-contact measurement of coating layers using the isotope-based backscatter method.

The number of measuring heads required depends on the type of application (wet or dry).

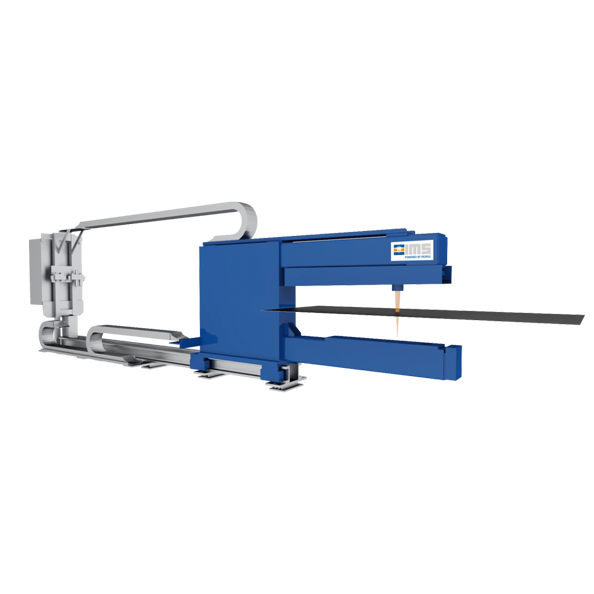

The traversing measuring system measures the individual coat layers (primer & finisher) over the entire strip width.

To this end, the characteristic properties of different types of coating can be stored in a database.

coat thickness measurement

quality control

coating database

optional:

coat layer control

Special Features

- quick and accurate measurements

- high reproducibility of measured values

- modular measuring head

- low maintenance costs

- highest availability

- fast return of investment

- savings in production costs (lower paint consumption)

Reserve your personal consultation appointment now!

Choose between a scheduled call back, a Teams video conference or simply use our contact form.

We look forward to hearing from you!

KR

Coating Weight

Measuring System

Coating Weight

Measuring System

Technical Information

Material data (typical for Aluminium Cold Rolling Mills)

Carrier material:

aluminium

Thickness carrier material (aluminium):

0.2 up to 3 mm

Width:

600 up to 2,100 mm

Coating material:

lacquers (epoxy, acryd, acrylate, acrylic, polyester, polyurethane, HDP, PVDF, plastisol, clear lacquers)

Typical coating area:

5.0 – 400.0 μm (dry)

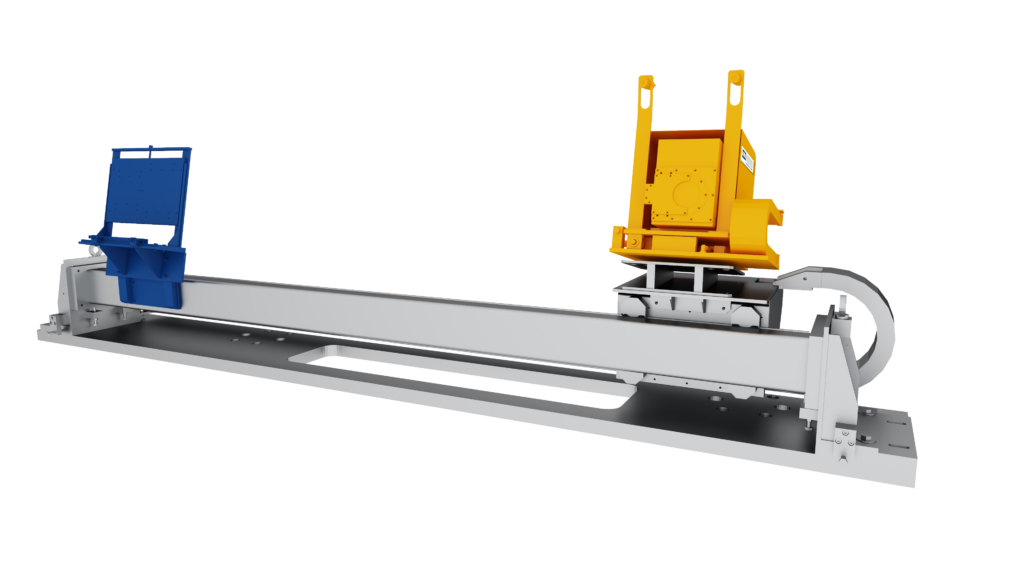

Measurement system data

Gauge type:

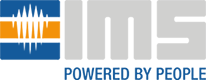

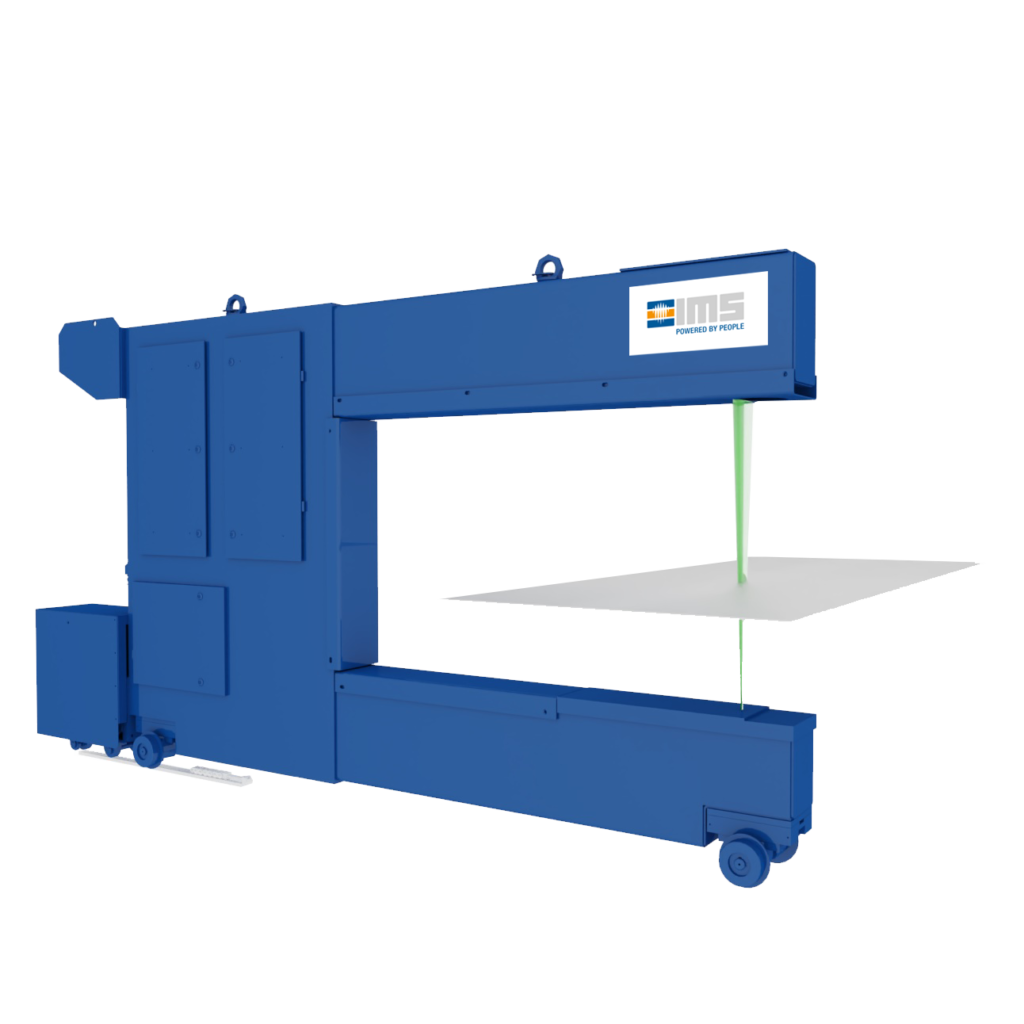

traverse with one measuring head (traversing)

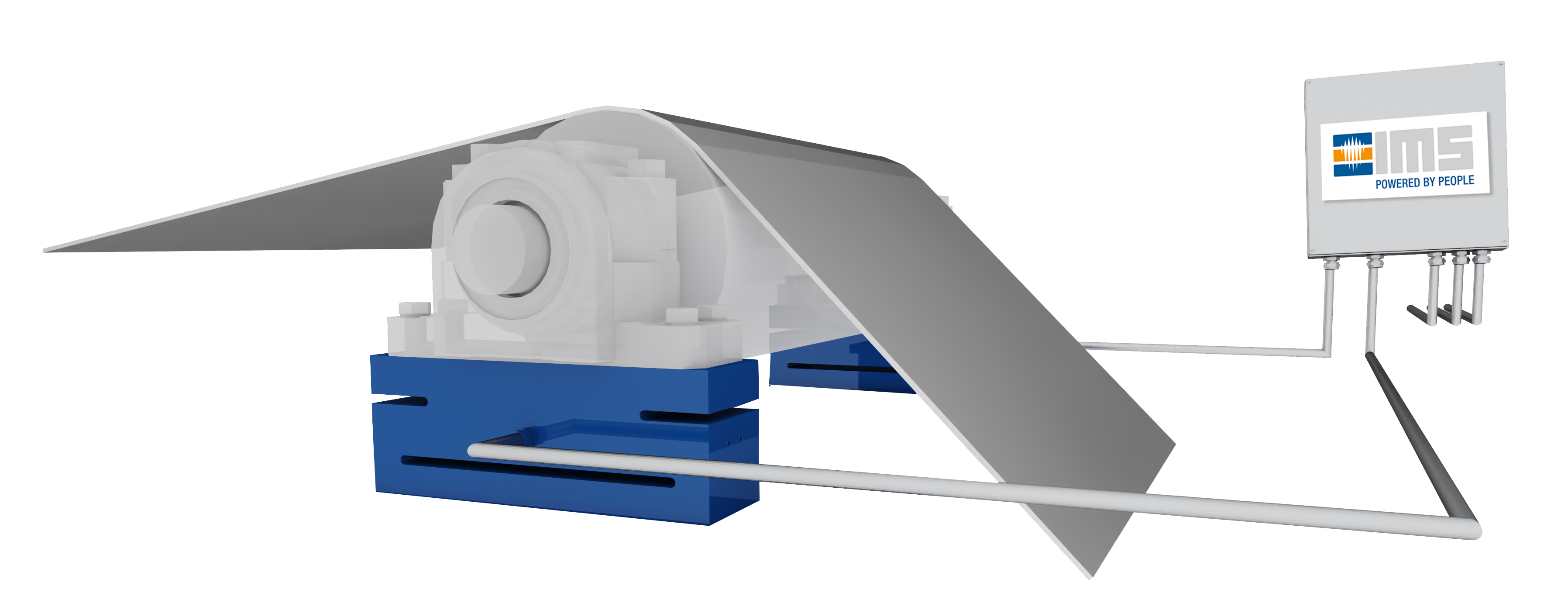

Radiation Source:

Kr-85 spotlight activity from 7.4 GBq

Detector type:

KG 90

Measurement spot size:

Ø 120 mm

Typical working distance:

approx. 30 mm

Traversing speed:

0.5 up to 8 m/min

Measuring dynamics

Sampling rate transmitter:

10 ms

Measuring time constant (analogue) TCA:

200 ms

Total time constant:

10 ms

Measured value output and processing:

200 – 2,000 ms (adjustable)

Measuring accuracy (2 sigma values)

Short-term drift, 4h (IEC 61336):

< ± 0.2%, not better than < ± 0.1μm

Reproducibility:

5 – 25 μm coating thickness < ± 0.3 μm

25 – 50 μm coating thickness < ± 0.5 μm

50 – 100 μm coating thickness < ± 1.0 μm

100 – 200 μm coating thickness < ±2.0 μm

200 -400 μm coating thickness < ± 4.0 μm

Statistical noise (2σ) :

(effective time constant)

TCE = 2.000 ms, TCE=TCA+TCD)

5 – 25 μm coating thickness < ± 0.1 μm

25 – 50 μm coating thickness < ± 0.2 μm

50-100 μm coating thickness < ± 1.0 μm

at 100.0 – 200.0 μm coating thickness

at 200.0 – 400.0 μm coating thickness

Measure.Inspect.Detect.

Product Catalogue for Aluminium Rolling Mills

- Learn more about the product portfolio of our high-precision measuring systems for aluminium hot strip rolling mills and cold strip rolling mills

- Standard systems for measurement and detection of slab dimension, thickness, thickness profile, length, width, temperature, speed, 2D surface inspection as well as various special systems

- Special designs possible on customer request

IMS Measuring Systems for Aluminium Cold Rolling Mills

(Aluminium Hot Rolling Mills)

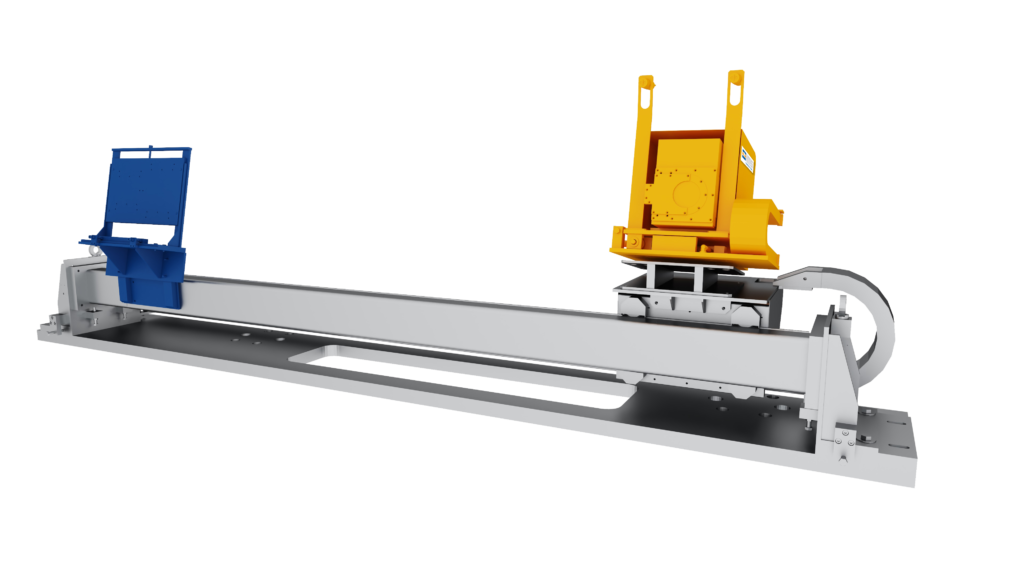

XR Traversing Thickness Profile Measuring System

(Aluminium Hot Rolling Mills)

XR Traversing Thickness Profile Measuring System (cold rolling mill)

(Aluminium Cold Rolling Mills)

(Aluminium Cold Rolling Mills)

(Aluminium Cold Rolling Mills)

(Aluminium Cold Rolling Mills)